Bought a WMM plant which promised productivity at lower costs? Instead ended up maintaining the Wet Mix Plant frequently? We have seen contractors having to waste a lot of valuable time maintaining the plant while leaving aside the job of road construction aside. Well, no one will like to be in such a situation. Will you? This situation can get worse when you know that your 200 tph wet mix plant. It is not producing more than 170-180 tph while the competitor’s plant is. The gears fail frequently and mixer breaks down frequently and requires maintenance. You got this plant after visiting the manufacturer and believed what he said. The presentation and price given was tempting. This equipment was supposed to give you tension free performance whereas it is giving you headaches.

Here we are talking about situations assuming you have a skilled operator for the wet mix macadam plant who knows the operation and maintenance of the machine. There may be many reasons for the breakdown of any equipment. we cannot always blame the manufacturer. Even a well made plant can have frequent breakdowns when the operator is not skilled.

For Sale Wet Mix Plant – WMM Plant Manufacturer

We understand that any equipment is and will be subject to rough and continuous usage and will be set at projects requiring being completed in specific time frame. You don’t want to compromise on the accuracy or the productivity of the equipment.

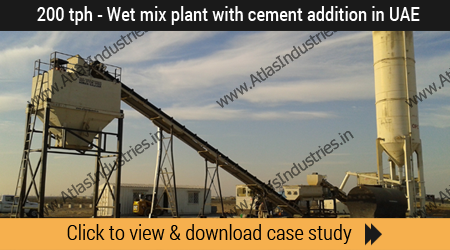

Atlas Industries has solutions to your needs and we have come up with proven design of wet mix plant. We believe more in quality and prefer that when equipment leaves our factory it is pre-inspected for quality.

In this article I will be highlighting key points as to why buyer should prefer our wet mix plant over other manufacturer. We will try to put forward advantages which are not in other wet mix plants.

If we start with the cold feed bins, you have the option to store four different types of aggregates (even sand). The bins are with variable speed drive motors to control the required aggregates as per your mix design. We have designed plants with more than four bins to accommodate variations in aggregates.

The weighing is done by the load cell on the charging conveyor when the aggregates are transferred to the pug mill unit.

Pug mill mixing unit is the one with advantages not offered by many. This unit has to be the best and maintenance free because it is subject to the most torture. Since, you need to squeeze out every dollar spent on buying and using this machine a maintenance free pug mill will help you achieve that.

There are two shafts on which the arms and tips are supported. The arms move opposite to each other resulting the arms and tips to move and do the mixing of the material. Each shaft is supported by three pedestals (UCF 218). Reason: The two pedestals near the gear will be able to handle torque in a better manner compared to a single pedestal offered by others. You get a vibration free pug mill.

What if you get a bigger 5 inches shaft for the pug mill? You will be happy, right? That’s what we have done, when you buy Atlas wet mix macadam plant, what you get is a 5 inches shaft which you know will not bend easily and will stay longer with the plant. We hate complains related to shaft replacements.

Our policy and never ending tryst to give you quality plants, do not end here, the shafts mentioned above are un-slotted. Yes, you read it right. The shaft is heaver and is also not slotted. We prefer putting distant pieces between the mixing arms. Your advantage here? The material will not come in direct contact with the shaft because the shaft is not exposed. Expect better life from both the shafts.

In our soil stabilization plants, the two arms are opposite to each other and similar with tips and not with alternate arms and tips like offered by some. Since a customer buys a plant expecting a faster and homogenous mixing of the wet mix material he should get everything.

The liner plate is replaceable along with arms and tips. Tips are Ni hard. We have kept the cost of replaceable parts surprisingly cheaper considering the genuine quality. Our plants always come with optimum sized storage silos so that you can enjoy uninterrupted production without stopping the plant if a truck is delayed.[/su_column]

We have solutions for storage and addition of cement in the pug mill. If your mix design demands? So, the standard control panel is user friendly and for those who demand extra. PLC control panel can be offered.

So now you know who to contact when you require a quality wet mix macadam plant assuring years of tireless and honest service.