Wet mix macadam plant by Atlas is an effective equipment designed keeping in mind the end user. We want our customers to experience high production, lower breakdown and lowest operating costs. Our equipment are designed for rough and continuous use. This WMM plant can work effortlessly under extreme conditions.

Pug mill with replaceable liners, arms and tips and with host other features mentioned below is giving tough competition. It is also possible to add cement in the mix if the design demands so. We have numerous installations and we have proudly put photos of wet mix plants installed worldwide our website as a proof of our quality.

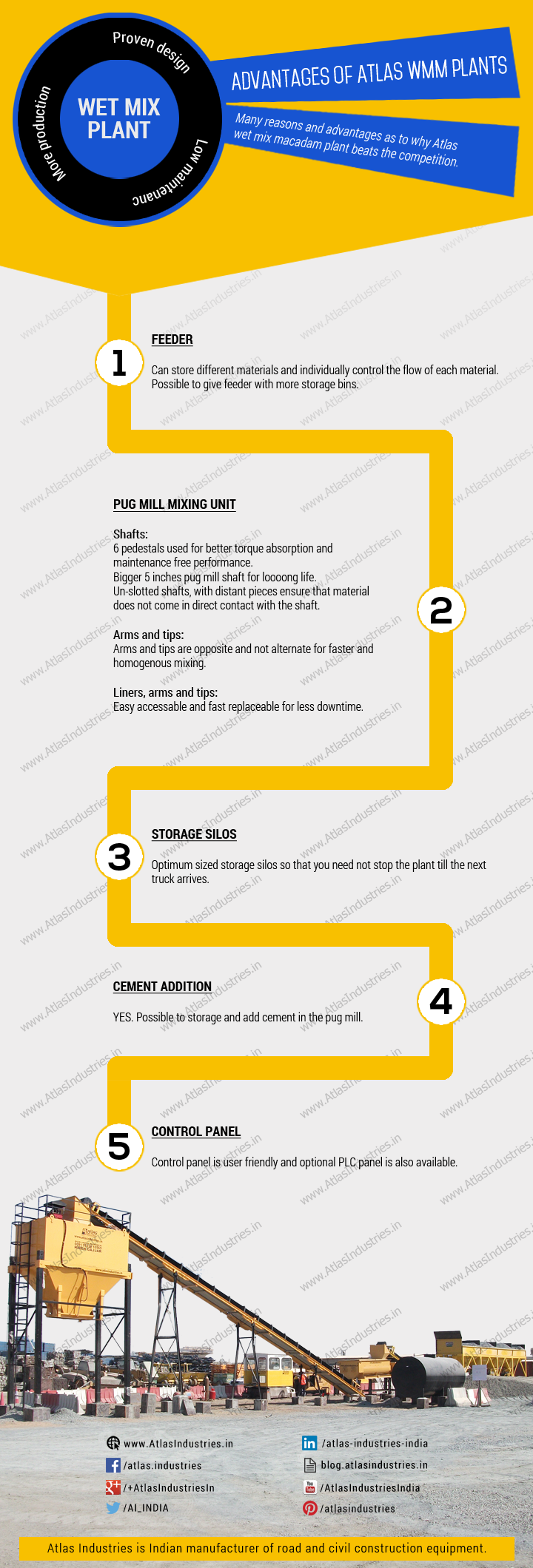

The below infographic on soil stabilization plant explains advantages of our offering. Click on the image to go to the product page.

Wet mix macadam plant by Atlas is a very effective machine which makes wet mix easily. Atlas wet mix plant helps to achieve higher production with savings in energy and is low on maintenance. The solid quality of the equipment is the reason that the same is preferred by many contractors worldwide. We have exported wet mix plants to many countries like UAE, Myanmar, Malaysia, Libya, etc.

Some strong advantages of Atlas WMM plant is as:

The success of a WMM plant depends on the compatibility and smooth performance of its components. The perfect combination and smooth working of all WMM components is must. All our components are designed to be sturdy and smooth operation of the equipment. Some of the key advantages are as below:

- We use three pedestals for each shaft. This helps to elongate the performance of the shaft.

- The size of the shafting used in the pug mill is 5 inches. The shafts are unslotted.

- Atlas supplied pug mill with wet mix macadam plant are equipped with high quality materials. We do not make slots in the shaft to fit pedal arms. We have given distant pieces. This helps to increase the life of the shaft.

- In our design of the wet mix plant pug mill, we have two arms opposite to each other and similar with tips.

- If cement addition is required, we can supply the machine with a cement silo or a small cement hopper for addition of cement into the mixer.

- An advanced PLC type control panel can also be provided along with the machine.

If you are looking for a quality equipment, contact us today.