Atlas has manufactured portable asphalt batch mixer in capacities 80 tph, 120 tph and 160 tph. It is a truly mobile asphalt plant. We can install this machine in 2 days. This is big advantage. The tower unit is mobile and on a single chassis.

Components of Atlas Batch Type Portable Asphalt Mixing Plant:

The Atlas batch type portable asphalt mixing plant consists of 9 components. Mobile asphalt batch plant is best and ideal road construction machine for sale from India. Best for you. If you want to shift sites frequently? It is designed to install with 1 single crane. All these parts are fully mobile. The plant is designed so that it is very easy to change sites. Even installation time is lowest making it ideal to shift places quickly.

Portable Asphalt Mixing Plant Components are as below:

Atlas make portable asphalt mix plant comes with components that are all mobile. It is ideal for customers who want a machine that can be setup in minimum possible time. It is a batch plant but does not require efforts to start. There are host of features that make it ideal equipment.

- Cold feeder bins: They are for feeding aggregates.

- Drying drum: It is for drying hot aggregates.

- Bag filter: Bag filter removes fine dust particles. It acts as pollution control unit.

- Bucket elevator: Bucket elevator is for transfer of hot aggregates to the top of tower unit.

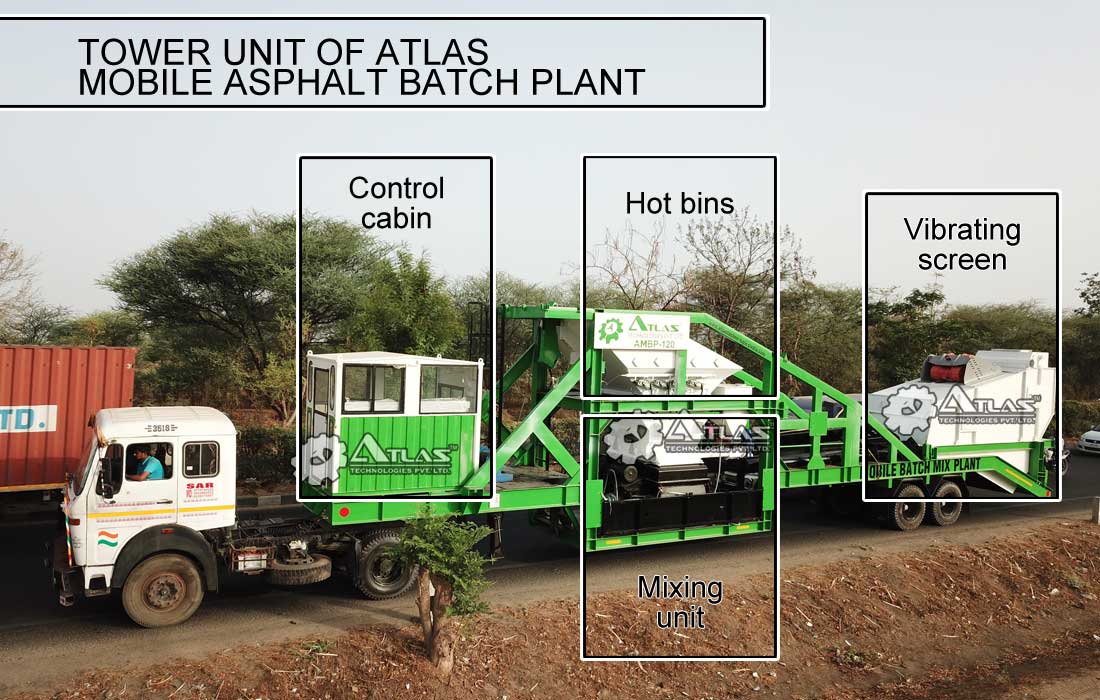

- Tower unit: Tower unit consists of vibrating screen, hot bins and mixing unit.

- Bitumen tanks: Bitumen tanks come with thermic heater. It will store and heat bitumen. Pump will transfer bitumen to the weigh hopper.

- Fuel tank: Fuel tanks will store fuel for the dryer burner

- Mineral filler: This unit is for adding mineral / additives to the mixing unit.

- Control cabin and panel: Control cabin houses the control panel. The mobile asphalt plant is controlled and operated by the control panel.

Features of portable asphalt plant for sale:

Atlas portable asphalt plant comes with many features. Mobile asphalt batching plant is available for sale in capacities 80 tph, 120 tph and 160 tph. The machine is designed to work in small site. It can be easily transported.

Key features are as below:

- Truly mobile design

- Compact plant

- Foundation less design

- Installation in 2 days

- Pre-wired

- Containerized design

- Plug and play system for quick installation

- Only use of 1 small hydra crane for installation

- Each chassis with king pin attachment and pneumatic braking

- Same sized mixing unit like stationary asphalt batch plant

- Enough space for maintenance

- Tower unit erection by hydraulic jacks

- Control panel with PLC control panel