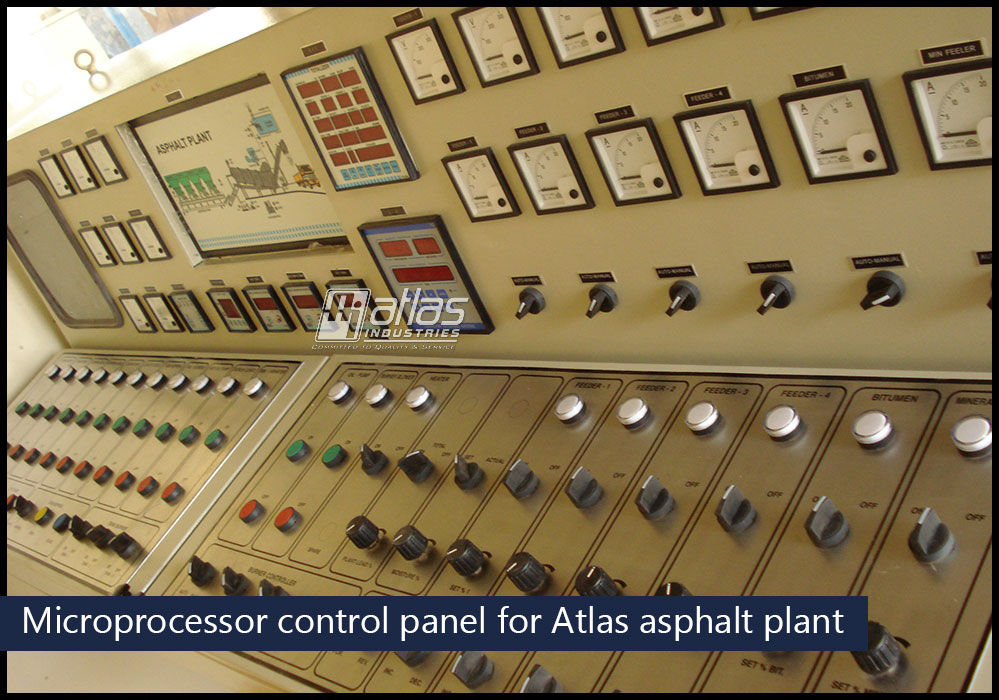

PLC Control Panel is a gigantic microprocessor. Controller Unit is designed for customized high end automation. A PLC may contain many microprocessors. PLC are preferred over microprocessor in automation. Hence in our asphalt and concrete plants we have option of PLC control panel. It allows us to have high degree of accuracy and customization. PLC is Programmable Logic Controller where high degree of accuracy, reliability, customization and precision is required.

PLC Control Panel can take input from various sensors and give logical output. Microprocessor Controller is possible to view this data in a graphical manner through a HMI or a monitor. In a concrete or asphalt plant we need to observe many readings / data. Combine the same to graphically represent the same on a screen. Even the basic functionality like increasing or decreasing any parameter will be easy.

How does a Asphalt PLC Work?

PLC or Programmable Logic Controller is a computer which is mostly used for industrial applications and industrial automation. PLC Control Panel can be used to automate a simple process or function of a machine. It can even be used to manage a complicated process. PLC Control Panel advantage lies in the fact that it can be customized. It receives information from connected sensors. This data that it receives is used to process the required data. Data processed is used for some calculation or displayed as required on the screen. It can also be used to start or stop any process. PLC is flexible and easy solution. We can modify the program as per our requirement and make it suitable for our needs.

PLC panel for asphalt mixing plants

In an asphalt plant this can be used to do some calculations like displaying weight, temperature, total tonnage. PLC Control Panel can also be used to set cycle (batch) time, gates open close timing, alarms, etc. We can start or stop the machine from PLC. It is also possible to store and display data as per different parameters. Production reports can be generated and printed by few clicks. With the help of customized software it is also easy to display reports as per different parameters.

PLC Panel For Concrete Mixing Plants

PLC control panel in concrete batch plant is a very useful tool to manage and customize the operation of the concrete plant. It can be used to start or stop a plant. PLC stores and allows us to edit mix material recipe. It also allows us to set batch timing. We can set open close type of cylinders, start-stop timing of belts, etc. PLC will help to store mix material data in different formats and print the same. We can set required weight for each bins of the mixer, concrete, water and also additive. Entire process can be displayed on main screen.

SCADA

SCADA is acronym for Supervisory Control And Data Acquisition. As the name suggests it is used for accessing a panel from remote location and get its data. SCADA is a system of hardware and software used by organisations to solve many purposes like:

- Controlling industrial process locally or remotely: You can be travelling at any part of the world and if you have internet with you and at the plant then you can remotely access the control panel of your machine. We use this also to update software and to solve problem.

- Monitor and gather data: Another advantage of having SCADA in your system. You can see, gather and monitor real time data.

- Interact with other devices through HMI: Once connected to the system via HMI we can access data of connected devices like valves, motors, pumps, burners, etc. We can also control the operation of these connected devices remotely.

- Troubleshooting: Timely troubleshooting is very important when your project deadline is near and you need to complete things on time. If anything goes wrong or suppose you are not able to figure out any particular problem then remote access taken by your manufacturer can be a life saver for you.

SCADA definitely has advantage over the normal control system without SCADA.

Difference between PLC and microprocessor.

PLC Control Panel is a big microprocessor. It does same things but at higher speeds and performance. Its main advantage is that it can be customized. We can also add modules at later stage and do changes in the software in Asphalt plant control panel. This makes it very easy to adapt the machine to changing situations.

Some advantages of PLC:

- PLC Control Panel is a microprocessor based highly customized product for high end applications.

- It can be programmed to control anything.

- Maintenance is less.

- Troubleshooting of PLC is easy.

- It can be updated at site or even remotely.

- It is programmed with a PC making it extremely user friendly.

- It is reliable and fast.

- It is better in cases where dust and humidity levels are more. Hence it is preferred choice for asphalt plants, concrete plants.

- They can easily establish communication with other controllers.

- They can integrate display units like HMI which makes operation of any machine simple.

Disadvantages of microprocessor:

- Programming is hard because it understands only machine language.

- It is a logic controller but in order to make it do another thing a lot of tedious changes need to be done.

- They are machine specific.

- Development is tough

- Development time is more.