Choosing and selecting best asphalt plant is not easy especially if you are new to the industry. There are so many things and parameters that have to be considered. The very motive behind purchase of the asphalt plant is to have a machine that is right for your needs and that it helps to complete your projects (target) without troubles. The best way to do this is to select equipment as per the market demand.

Purchase of this equipment is very critical for your business and it cannot be compared to any other road building equipment that you may have. This purchase will be a capital investment which will last long for many years as an asphalt plant cannot be dumped off easily. A haste purchase related decision can prove fatal in the same. When you go and meet many different companies you will have different views from different people and sometimes these statements can be different and vary from people to people. This can create a lot of confusion and if the decision goes wrong, there is no way back.

We are not just talking about low production or breakdown or poor quality equipment here. If you have made a road without proper mix the damage may not be immediate but after years when the roads starts to come off and this can lead to huge looses for the company. A very clear view, to understand what you require and in What Budget to make sure that it suits Your Project, is what important to understand before you even think of approaching asphalt mixing plant manufacturers.

LONG TERM PLANNING:

Long term planning is a must because this equipment will not just be used for this project but for other projects that you may procure in future. If you have a small project consider settling for a mid size plant which is a bit bigger so that when you complete a project you can confidently take a bigger project without investing in another machine of higher capacity. It is also important to understand what your competition is doing and get equipment accordingly. Most important decision will be to get hold of a machine which may be a bit expensive to own but promise low production costs – the reason – you may be using the equipment for years and low production and maintenance means that you will be able to reap benefits each year. It is important to have a skilled operator and also acquire some basic knowledge on the same before you go out and meet asphalt plant manufacturers. Get basic reviews on the equipment available in the market now and the current trends. Also make sure which manufacturer is better in terms of service factor and promises to deliver spare parts at reasonable costs.

SOME OF THE BASIC FACTORS THAT YOU NEED TO UNDERSTAND BEFORE YOU CAN GET STARTED

- Types of asphalt plants

- Styles of asphalt plants

- Size of asphalt mixing plants

- Plant components and customization

- New or used

- Transportation

- Compare

- Role of an asphalt plant operator

Types of asphalt plants:

There are two basic types of asphalt plant available in the market today – batch type and drum type.

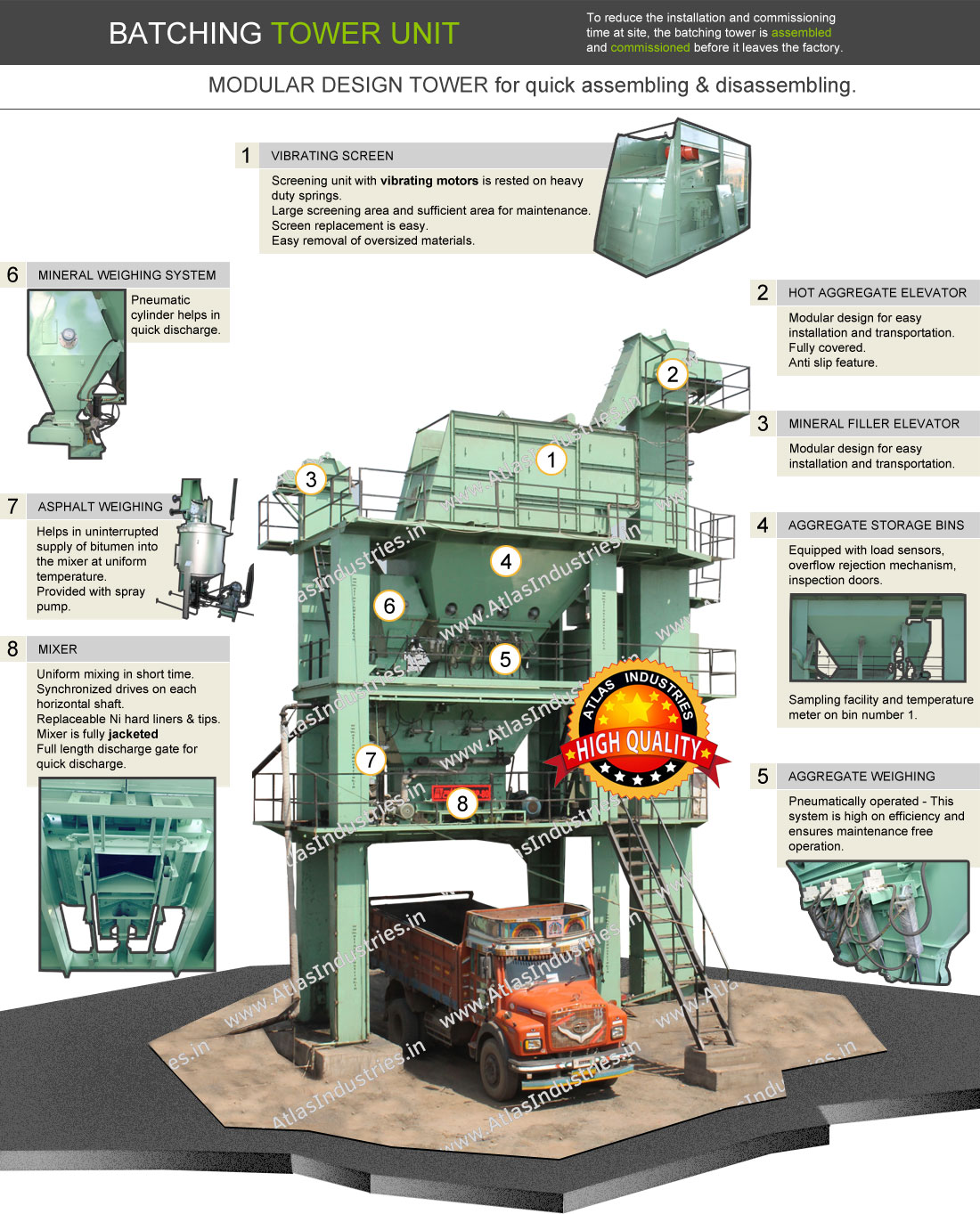

BATCH PLANT: Asphalt batching plant makes hot mix asphalt in batches. The working of the same is simple and as follows. There are cold aggregate feeder bins that store and supply cold aggregates to the drying drum. The drying drum does the task of moisture removal for the aggregates so that they can bind easily with bituminous material. Once the aggregates are heated and leave the drum, they are transferred to the vibrating screen where they are separated and stored in separate compartments as per the sizes. The size of the screens and the number of screens may vary from plant to plant. The storage compartments of the different aggregate sizes are known as hot bins. The aggregates are then weighed and then introduced into the mixing unit. This mixing unit is a twin shaft batch mixer designed to homogeneously mix the weighed aggregates, bitumen and filler material. Like aggregates, the bitumen and filler material are also weighed separately before they get introduced into the mixing unit. After the end of this mixing process, the gate at the bottom of the mixer opens and the materials fall into the waiting trucks or into storage silos.

This equipment can make reasonable hot mix asphalt from any material. One of the key features of the asphalt batching plant is that you can change the mix specifications a.k.a. recipe anytime during the operations. You can also customize the size of the screens of the plant. These screens can be made available in different sizes and are easy replaceable ones so that you can control the exact size of the aggregates that you want to use. These factors add considerable value to this equipment. It is also to be noted that a batch plant will take almost 30-35% of its time waiting for the bins to weigh, for pug mill mixer to get empty, etc.

BOTTOM LINE:

If you are looking for a machine and you do not want to change the mix specifications often and are concerned with high production then this is not the right machine for you.

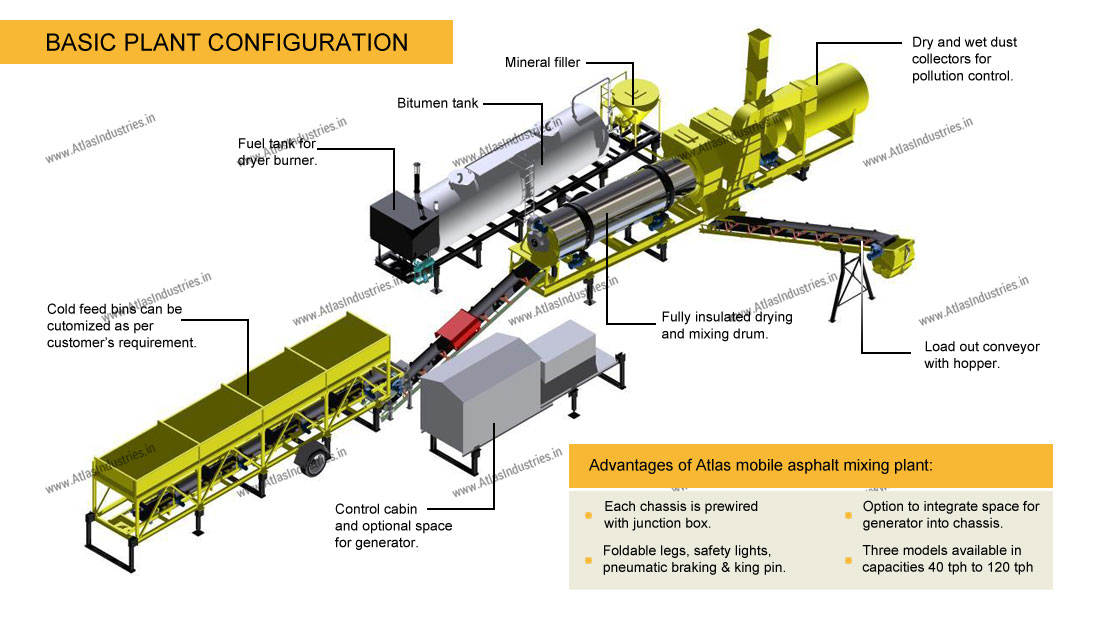

DRUM PLANTS: Drum plants also known as drum mixer is a continuous type plant (parallel flow type) that makes hot mix asphalt in simplest form. The cold aggregate feeders store the aggregates in separate bins and transfer the same to the drum by a conveyor – same like the batch plant. The difference in the process is that while the aggregates are transferred to the drum, they are weighed on the conveyor. This drum also acts as a mixing unit along with drying unit. The first half is the drying zone (removal of moisture) and the second half is the mixing zone. The addition of bitumen and filler material is in the second half of the drum away from the flame. They are thoroughly mixed as the drum rotates. As they come out of the drum they are transferred to the waiting truck or storage silo. When we speak of asphalt batch plant vs drum plant the difference are very much.

The very fact that the asphalt drum mixer equipment uses fewer components and is easy to own and maintain makes it ideal choice for people who want high volumes of production in a small space.

BOTTOM LINE:

This is not the machine for you if in-case you want to change mix designs frequently or you want the ultimate machine with full accuracy for your project. This machine will take up less space is easy to understand and operate. “Since it has less moving parts the cost of owning, running and maintenance is also the lowest compared to a batch mixer.”

COUNTERFLOW ASPHALT MIXING PLANT: This is also a type of continuous plant but the key difference between the drum mixing plant and this design is that this design incorporates separate zones for drying and mixing. As soon as the weighed aggregates enter the drum they are treated to a flame for removal of moisture. As the exit the first chamber they are passed to the other zone which is the mixing zone. After mixing, the aggregates are led to the storage silos or waiting trucks to be delivered to the job sites. Compare the quality of the hot mix from this machine vs drum mix plant vs batch mix plant and you will know the difference.

BOTTOM LINE:

Since this is a counterflow plant, the aggregates are heated in a counterflow process making it more efficient compared to the drum mix plant. You can opt for this design if you are looking for a machine which is between the traditional drum mix plant and a batching plant.

Styles of asphalt plants:

There are two basic styles of hot mix plant they are stationary or mobile asphalt plant. However one would complicate the situation, it is not difficult to decide between the two types. A simple parameter you can set to decide between the two types. It has to be noted that the mobile plants will cost substantially more than its stationary counterparts. If you are planning to move one in a few years it is ideal to go for a stationary model because here the cost of transportation will be less than the cost of mobilization. In case you are looking to move few times in a year then seriously consider going for a mobile plant. While option for a mobile asphalt plant, it is necessary that you consider buying the accessories that are mobile.

If your plant installed is very far away from your site where construction is taking place calculate the time required for the truck with full load to reach the site at peak time. This is important because you will have line of machinery waiting for the hot mix asphalt to arrive and your truck load will be stuck in traffic. Since most of the mobile plants come prewired and easy to fit and run components, in such cases it is always advisable to go for a mobile plant. Mobile mixers usually take up less time to assemble and disassemble.

If you are going to buy a mobile plant and working for at least 6 months at a place without moving then do not buy tyres with the plant. Check the tyre sizes and buy them later locally when required as rubber items get spoilt when not put to used more often.

Size of asphalt mixing plants:

Size of the equipment will totally depend on the production that you require from the machine. Decide what type of project you have in hand and in what time the same has to be completed. Calculate your required capacity of the equipment in tons per hour. For eg. As per the above calculation, the capacity you get it 40 tons per hour, it is advisable to go for a bigger machine like 50 or 60 tons per hour. The reason is that you may not be able to use the machine continuously as calculated in terms of hours. There will be interruptions like non availability of material, labour, machine breakdown, etc. that will hamper the production and the plant will suddenly seem way smaller. When we look at the future and the nature of jobs that your company may be ready to take, it will be advisable to go for a bigger machine. Speak with the asphalt plant manufacturers and share with them your mix material design and conditions where this machine will be operating. The more details you share – the better. If you are going for a continuous plant, the production of the same depends on different factors like the aggregate moisture content, percentage of dust, etc. When the manufacturer understands the different factors and he has sufficient data, he can guide you into buying the right capacity equipment.

If you are looking to sell hot mix asphalt and are targeting to produce say around 3000 tons in 8 working hours, it will be advisable to go for a 400 tph machine. Also consider the time in a year when your plant will be running for full 8 hours at full capacity producing 3000 tons in a day. If it is 10-15% then you can easily consider going for a smaller plant of say 200 tons or 300 tons per hour. The initial cost of both the machine will be very huge and the operating cost of the 200 tph plant will be lower than a 400 tph plant. Analysis the market demand and forecast the same then only decide what capacity you want to go. It is also worthy to note that a much smaller hot mix plant is not advisable as you will not be able to produce enough content in short time. A smaller plant may also force you to go for another unit in short time and prove to be a bad decision. Also it is not advisable to go for a plant which will stand idea for too long proving its worth inefficient. A plant is ideal when it is made to run at about 80-90% of its capacity most of the times and not made to stay idle for long. If the plant size is big, it will fill up the storage silos faster and it will have to be shut down for some time for the trucks to empty the silo, this adds up to inefficient production and higher cost of production. A smaller plant will be working slowly but with a storage silo it can run continuously for long duration. This will sometimes prove to be worth in the long run.

Considering the site installation space is also very important. If you are working in a tight space a small machine is advisable. If your project is at a hilly area, probably you will have to shed a lot of money to get the equipment up there, in such cases it is a wise advice to go for a small machine.

Plant components and customization:

Very important to consider which accessories are suited for you and will give best return on investment in the future. Some of the common accessories are as below:

COLD FEED BINS: Customizing cold feed bins is required if you are planning to use more types of aggregates than required. Most of the plants come with 3 or 4 bins as standard configuration. If you are going to use 4 aggregates as per your mix design and your design mix also required addition for sand make sure you get plant with minimum 5 bins. If you are going to use sand in two bins speak with the asphalt plant manufacturers and get two bins equipped with two vibrating motors. This will be useful during moist conditions.

NUMBER AND CAPACITY OF THE ASPHALT TANKS: Simple calculation that totally depends on how far your supplier of bitumen is and how frequently you are going to need the resource. It also boils down to how frequently and for how long you are going to use the machine. You need to answer this before you decide the capacity of the tank required. If you are having a tank of size 20 tons means that you can use almost 19 tons because you will be leaving some bitumen on top of the heating pipelines. So you have 19 tons of bitumen, you are running the plant at capacity say 100 tph and adding 5% of bitumen per tons of hot mix. 5% of bitumen per tons means 50 kgs per tons. At 100 tph this will be 5000 kgs of bitumen consumed in one hour. So before every 4 hours you will need a refill. In most case this is a troublesome situation. Hence it is advisable to go for a higher capacity tank or go for multiple tanks. Bitumen tanks with indirect heating are also available with some manufacturers which are more preferred in case you want to avoid ageing of bitumen. You can consider getting a mobile storage tank which can go and refill as and when required to avoid breakdown in the production.

STORAGE OF HOT MIX ASPHALT: Inadequate storage of hot mix asphalt will give you headache as you will have to shut down the equipment more often resulting in high cost per tons. Your small plant of 40 tph can be started early in the day to fill up the silo faster so that when the trucks are getting lined up you do not have to worry about waiting empty trucks as you have started early and are ahead of the time. It is important to note that you can start early and fill up the storage silo if you have a small machine but with a bigger machine you cannot start late. It is easy for a small plant to perform like a bigger plant when you have huge storage capacity but with a 50 tons silo and a 100 tph plant you can easily fill the silo in 30 min. If the truck does not arrive in that time you will have to shut down the production. Hence it is always preferable to invest in storage silo of bigger sizes.

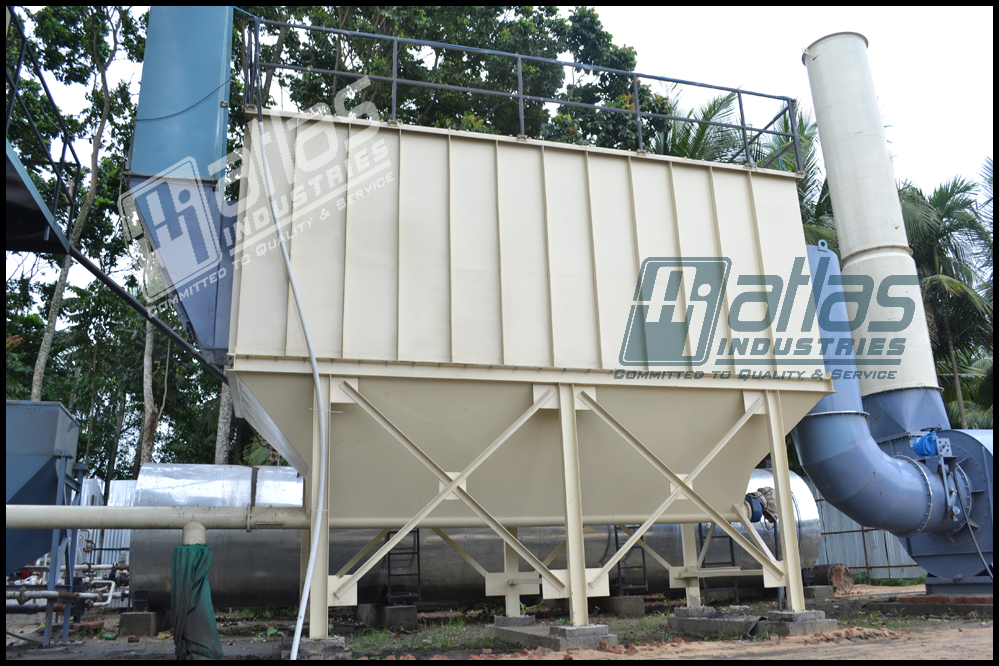

POLLUTION CONTROL DEVICES: Consider going with a manufacturer who offers primary and secondary pollution control units. Primary dust collectors use centrifugal technique to collect most of the heavy dust and settle them so that only light particles reach the secondary pollution control device. Secondary pollution device can be wet dust collector or bag filters. It is commonly known that bag filters are more costly when compared to the wet scrubbers. Bag filters are more efficient in terms of cleaning as they are capable of capturing most of the dust particles and harmful gases.

Venture type wet dust collectors use water to trap dust particles and they require maintenance of a sludge pond and the water has to be kept clean periodically. On the other hand bag filters do the cleaning as the gases pass thorough the bags entrapping the dust particles. Wet scrubbers are inexpensive to fit, run and maintain compared to bag filters. But if you are looking at a long term, consider going for a bag filter as you will not have any problems with the equipment with regards to the government pollution control norms.

BURNER UNIT: Select a plant burner which is simple and maintenance free. Make sure that you check the actual fuel consumption. Most of the manufactures would be able to give you an approximate figure of the fuel consumption when you give them details like your mix material design, fuel to be used, etc. Make sure that the fuel that you are planning to use is economical and easily available. Also check for other options available in your area. The fuel supply should be continuous. Now-a-days there are various options like natural gas and coal fired burner available, speak with the manufacturer and see what suits you.

ADDITION OF RAP: Reclaimed asphalt payment is fast catching up and there is increasing demand for plants that can do RAP also. It is important that you discuss with the manufacturer of your choice and decide on a machine that can do both virgin and RAP.

SPARE PARTS: Comparing the cost of spare parts between different manufacturers is important because in future you will need spare parts for maintenance of the plant. Make sure you go into details about what spare parts are suggested by the manufacturer and the cost of the package. Try and strike a deal where you can get the spare parts as complimentary from the manufacturer. Make sure that the electronic spare parts used in the control panel are of reputed make and easily available in your country.

CONTROL PANEL: This is one of the most important components of the asphalt mixer. Any compromise here will be a huge set back. Speak with the manufacturer and understand the basic controls. If possible let your operator get hands on the control panel software and spend some time with a running machine before you finalize the equipment. The control panel should compulsorily use components of reputed make and its cabin should be rust free. Make sure that the components used are easily available locally or can be replaced with a similar brand without any issue. Check the calibration process of the machine if it is very hard for your operator seek an explanation or a write up on the same for future records. The reason is that you will be required to do frequent calibration of the machine.

New or used asphalt plants:

Deciding between a new or used machine should be easy if you consider below advantage points for each type.

A new plant always comes with warranty, service support, help with installation, operator training and compliance with environmental norms -all as per your requirement. A new asphalt batch mix plant or drum mixing plant can be customized as per your requirement and you can choose or alter the layout of the equipment so that you can make maximum use of the available space at your end. Most of the companies should offer you installation support at reasonable rates as you will buy from them. You will also get trouble shooting, operating and maintenance support for few years as free from the manufacturers. If you are new to the business it is advisable to go for a new machine.

If you are a bit tight on budget and want to have a machine without spending more money try and get equipment which has not been used much. Make sure that it is sourced from a reliable source preferably from a manufacturer or from a place recommended by the manufacturer. Once you have decided on a machine, get it checked from a genuine service man or your operator to get an idea of the things that you will need to arrange to make the equipment a success. Ask as many as questions that you may have regarding the equipment. Also make sure to ask if certain components that are worn out can be procured or repaired in future if required or not? It is also important to have a decent and formidable service backup for the machine that you are going to buy. Also make sure that the availability of the spare parts for the next few years is available for the equipment that you will buy.

VIDEO: ASPHALT BATCH PLANT VS DRUM MIX PLANT:

Transportation:

Having thorough knowledge on the transportation dimensions will help you save a lot of money in the long run. When you know the dimensions and weight model wise you can straight forward make comparison between different options that are available to you. In case if you are tempted to go for a bigger model but the transportation rates are high which is exceeding your budget, you can consider skipping that idea. Most of the buyers forget the transportation part and in course end up paying more. Even by knowing the transportation cost you can easily get an idea of the total project cost.

Compare:

Comparison of different models specifications is very important before purchasing. This will eliminate any chances of emotional decision from your end. When you have a specifications sheet filled by respective manufacturers you can put each model side by side to avoid any confusion. This will take more time because some manufacturers will take time to fill up the specifications. But once you have the comparison from at least 4-5 or more manufacturers the decision making is really very easy and precise.

Role of an asphalt plant operator:

Asphalt plant operator will be spending most of his time with the machine – probably more than you. He is the one who is going to use, maintain and manage the equipment. It is important to keep him in loop and he is aware and confident of using the machine that you are about to finalize. If you have an experienced operator or an operator who is well versed – better.

If not, make sure that you select an operator who can foresee any problems, do basic maintenance and repairs, knows how to set the mix designs very well, knows the basic calibration process, maintains safety standards, maintain constant temperature in the plant, organize his team of workers and oversee all the plant operations.

More importantly he should be able to love the equipment, be alerting, willing to learn and adapt.

Conclusion:

Buying an asphalt plant will be one of the toughest decisions that you will take. If gone well it will reap huge benefits to your company. It is advisable to know the market size, potential and the key players before you think of investing in one. Do ample of research, ask questions to the suppliers and your operator. Understand the requirement of your potential buyer.

Few questions that may help you go through will be:

- Can I offer my buyer something which no one else offers?

- Can I make genuine efforts to procure customers considering that people will be reluctant to buy from me since I am new to this business?

- Can I get a skilled operator and are he and his team capable to manage and maintain the machine well?

- Can I be able to get enough volumes at least in the first year or two to justify the investment?

It is also advisable to speak and consult with many consultants and note down points that you may find important. Understand how your competitors got into this business and paved their way up – try and implement the same strategy if applicable.

If you are looking to do road works make sure that you have at least one project in hand that can make you happy. Make sure that the location of the plant is near the project because you will always need to lay the asphalt hot.

One of the most important points to be discussed with the manufacturer is related to the pollution control norms prevalent in your area.

Make sure that you have your mix material design ready and discuss the same with the manufacturers to avoid purchase of any additional components that you may not use in future. If you are looking to buy an old machine – make sure that you visit the equipment site to inspect it along with your operator. The same rule applies to the purchase of a new asphalt mixing plant.