Excon 2017 held at BIEC Bangalore, Karnataka, India is 9th edition of the premiere construction machinery exhibition. It is held from 12-16 December 2017 and is organized by CII (Confederation of Indian Industry).

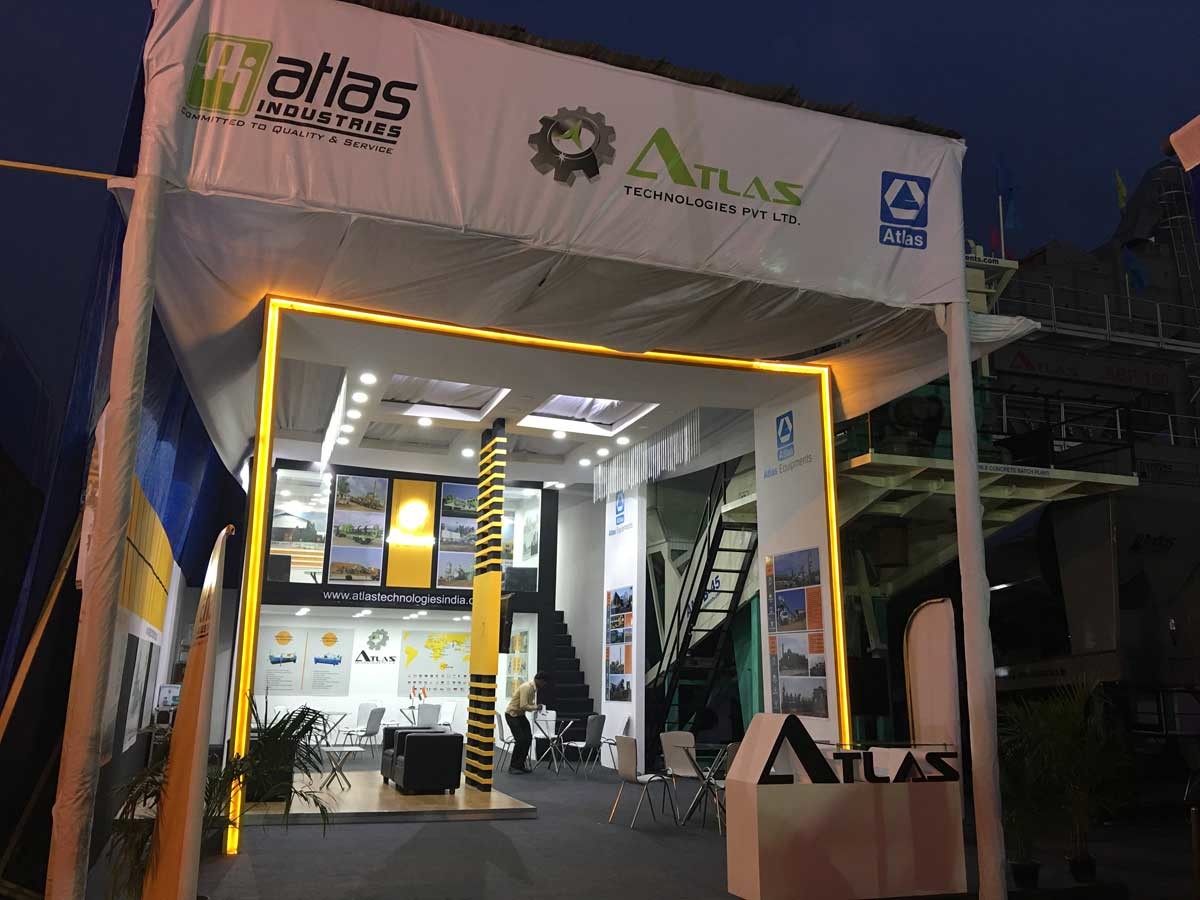

Atlas Technologies Pvt. Ltd., Atlas Industries and Atlas Equipments are three sister companies participating in the same.

We have received superb response across all product groups and have had a change to meet many customers from India and abroad.

Our location:

Green Lot

Stall No. OD 107

Some of the photos of the event are as below:

Video of the event of our stall:

Construction equipment at Excon

Atlas has got some of our construction equipment to feature at this 2017 Excon. We are displaying some machines like below:

• Drying and mixing drum of counter-flow asphalt plant. – 90-120 tph

• Drying drum and tower unit of asphalt batch mix plant – 160 tph

• Control panel of asphalt batching plant

• Mobile concrete batch mix plant – 45 m3/hr.

Drying and mixing drum of counter-flow asphalt plant with RAP – 90-120 tph

The drying and mixing drum of counter flow asphalt plant is the main component. It is the key component that allows drying and mixing to produce quality hot mix asphalt. The reason for displaying this component is that we are the most successful manufacturer of counter flow asphalt plant from India. We have successfully installed double drum type machines in several parts of India. This single drum counter-flow mixer is an addition to our current range. It is fitted with a long nose burner on the opposite end of the aggregates entry. The burner fitted is compatible with Diesel / LDO / FO. The first half of the dryer is for drying the aggregates and the second half is for mixing the same with bitumen to make HMA. It is also possible to add up to 25% RAP in the same. There is a RAP collar in the centre of the drum to facilitate addition of RAP into the mixing zone just behind the burner flame.

Drying drum and tower unit of asphalt batch mix plant – 160 tph

Drying drum is important part of asphalt batch mix plant. Tower unit is also important component for this machine. We have got a big 160 tph drying drum at display with burner fitted in the same for our customers visiting us at Excon. The tower unit along with elevator is also displayed. Tower unit comprises of vibrating screen unit, hot bins and mixing unit.

The vibrating screen unit is a four deck screening unit comprises of 4 screens laid one below the other. The different sizes of the screens will allow different materials to pass through each screen. After this the aggregates are stored into separate compartments just below the screening unit. This unit is known as hot bins. Hot bins consists of 4 compartments to store aggregates into different compartments as per size. Mixing unit is a twin shaft type mixer which is just below the hot bins compartment. It is heavily designed unit for homogeneous mixing of hot mix in short time. The mixing unit is comprised of a long gate just below the mixing unit for quick discharge of the hot mix.

Customers visiting us have had first hand experience at the product offered and also get change to climb up the tower unit. This has allowed us to get very close to customers and have them see and feel the product they are looking to buy.

Control panel of asphalt batching plant

We have got a full unit of the control panel of asphalt batching plant inside a cabin. It is equipped with SCADA interface. There is a computer and also HMI screen with the software loaded. Many customers who have visited us have taken advantage of this and asked us to give small demonstration of how to operate the machine. We have developed a software which is very user friendly.

In addition to the same we are giving demonstration to the customer for 2 important and notable advantages of our control panel.

• Demonstration of how customer can view live detailed reports of the asphalt plant without being physically present at the site.

• Demonstration of how we can access the screen and also do troubleshooting of the control panel sitting at our factory.

Both the above points will require internet connection at both the ends.

Mobile concrete batch mix plant – 45 m3/hr.

We have also got a mobile concrete batch mix plant of 45 m3/hr. capacity. It is featured with a new and improved twin shaft mixing unit manufactured by Atlas. This twin shaft type mixing unit is of capacity 1500/1000 liters. Going by the capacity this mixing unit can produce up to 60 m3/hr. The concrete plant is erected for customers to come and see the same. Many customers have climbed the stairs and also asked questions about the mixing unit. People who are new to the business have asked on how the concrete plant works and it gets easy when we can demonstrate on the machine. The control panel of mobile concrete plant is also there enclosed in a cabin. We are demonstrating customers to get detailed live reports when the machine is working without being present at the site. We are also demonstrating how we can access the panel remotely and do trouble shooting of the panel as and when required.

We are trying to get technology implemented in our machines that can benefit to the customer in a big way. Customers have also welcomed this decision and are happy with when they have seen at Excon.