WMM plants are important part of any fleet of equipment for a contractor who undertakes road construction jobs. Also known as soil stabilization plans, these are used to produce materials which help in stabilization of the soil prior to laying of hot mix asphalt.

In most of the cases, aggregates, sand is mixed with water along with some percentage of cement. The percentage of cement is usually 3-5% and may vary. Though in small percentage, cement will act as a binding material in the mixture. Then this mix material is laid to give proper strength to the floor.

Wet mix plant in India is sold with aggregate feeders, primary vibrating screen, charging conveyor with load cell for weighing the aggregates, pug mill mixer, load out conveyor and storage silos. A cement silo is also available with the plant for addition of cement directly into the mixing unit.

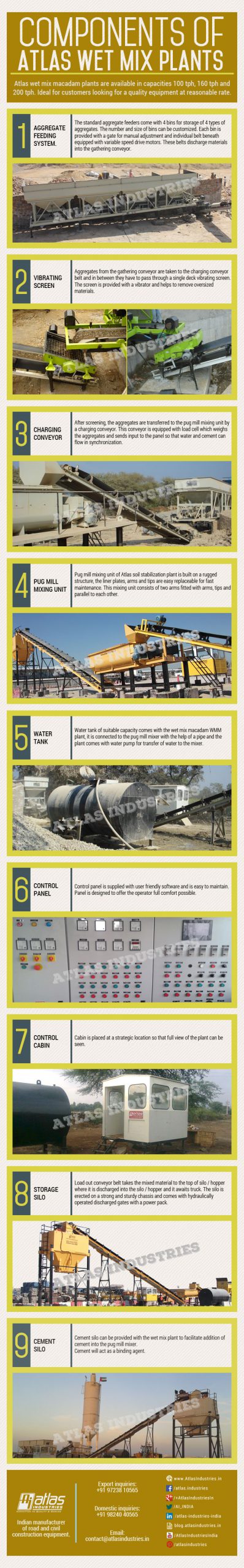

Components of Wet Mix Plants

Atlas make wmm plant is manufactured for tough conditions. The components of the wet mix plant are very heavily designed. In fact, the pug mill mixer which is the mixing unit is very strong. It is designed to take heavy loads with ease and perform smoothly. The design is simple and maintenance free. The shafts are unslotted and heavy and resting on 6 pedestals. Smooth performance, superior mixing and reliable service support from Atlas makes this a gem of a machine.

Below are the core components of wet mix macadam plant explained in brief:

- Aggregate feeding system: Standard bins come with 4 feeders. Each bins have individual gates for controlled floe of aggregates. The number and size of bins can be customized. Each bin is provided with a gate for manual adjustment and individual belt beneath equipped with variable speed drive motors. There is a bigger gathering conveyor below each bins. These belts discharge materials into the gathering conveyor.

- Vibrating screen: Aggregates from the gathering conveyor are transferred to the charging conveyor belt. While passing through the two belts they have to pass through a single deck vibrating screen. The screen is provided with a vibrator and prevents oversized material to reach the mixer.

- Charging conveyor: The aggregates are transferred to the pug mill mixing unit by a charging conveyor. This conveyor is fitted with a load cell. Load cell will weigh the aggregates. It will then send a signal to the control panel. This helps the panel to synchronize the addition of cement and water into the mixing unit.

- Mixing unit: Mixing unit is built on a rugged structure. It is a continuous pug mill mixer. All the liner plates, arms and tips are easy replaceable. It’s a sturdy mixer with easy to maintain design. This mixing unit consists of two shafts. These shafts have arms fitted on them parallel to each other.

- Water tank: Water tank of suitable capacity is supplied. It is connected to the pug mill mixer with the help of a pipe and the plant comes with water pump for transfer of water to the mixer. Depending on the input from the load cell, the flow of water is controlled.

- Control cabin and panel: Control cabin houses the control panel. Control panel is microprocess or PLC type depending on the choice of the customers. The easy to use software allows easy learning of the same.

- Storage silo: Suitable sized storage silos are available. They help in storage of the material before discharge of the material into the trucks. Silo is on a heavy structure with hydraulically operated gates for open-close mechanism.

- Cement addition: Cement addition is possible with the help of cement silo or hopper. A screw conveyor is equipped for addition of cement into the mixing unit.

Wet mix macadam is made by use of stone aggregates, water, cement and or emulsion. All these items are mixed in desired proportions and then laid for a granular sub-base.

Wet mix macadam method includes spreading of well mix material prepared for sub-base. This includes aggregates, water, cement and or emulsion.