Asphalt storage bitumen tank can be configured and supplied with wide options and sizes. Bitumen tanks are available with direct heating system or indirect heating system. We are manufacturer of bitumen sprayers tank and asphalt batching plants in India.

Direct heating bitumen storage tanks come fitted with internal coils and burner at one end of the coil the burner. The heat generated from the burner flame flows from inside the pipe and is responsible for heating of the bitumen inside the tank.

Indirect heating bitumen tank for sale come equipped with pipelines inside that allow flow of hot oil from inside the coils. These hot oil transfer coils come from an external hot oil heater fitted with a burner. Continuous flow of the hot oil from the heater to the tank and back allows fast melting of bitumen.

The construction of these tanks are very important and done with care by Atlas. To ensure that the end product is the very best and serves for years to come.

The first step in the manufacture of these bitumen tanks is the construction of the base chassis as per the bitumen tank design. The base chassis is a very important part here. Because it provides support to the tank shell. When the tank is lifted for transportation. The base chassis provide adequate support for the tank shells. There are many manufacturers who do not provide these tanks with the chassis. They do this to reduce to the manufacturing cost.

The second step is to take the plates and bend them for the construction of the shell. When these plates are bent, care is taken to ensure that the diameter is same for all the plates otherwise it will be problem welding them together. Afterwards these plates are welded with due care ensuring that there is no leakage.

The third step is to make the internal heat transfer coils. These heat transfer coils are at the bottom of the tank and are responsible for passing the heat thoroughly inside the tank. These coils are also joined with each other with care ensuring that there is no leakage. These coils are then placed and fitted inside the bitumen tank.

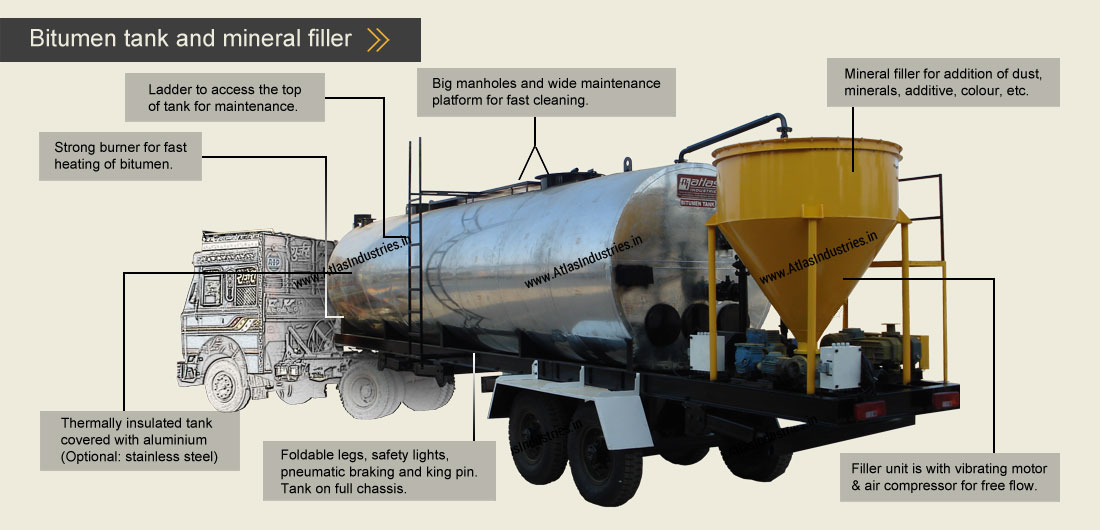

The fourth step is to cover the entire shell surface with glass wool. This glass wool will help retain the heat inside the tank. The thickness of the glass-wool is 50 mm covering the tank from all the sides. Over this glass wool, a sheet of aluminum or stainless steel is claded to make the tank look visually appealing. Along with this, the tank ladder, platform, level guage, manhole, etc. is fitted to complete the tank structure.

A manual temperature meter on the tank and a thermocouple is important unit for any asphalt tank. The rmocouple allows having a look of the bitumen tank temperature sitting inside the cabin.

The tank is also fitted with a guage that allows viewing the level of bitumen inside the tank.

In the end, the pumping station is assembled with the tank. Pumping station includes main component like bitumen pump, gears, motors, pipelines, burner, fuel tank for burner, etc. Completion of these units will allow the smooth discharge of bitumen.

After completion and fitment of all the units, the tank and pipelines are thoroughly checked for any leakage and then painting process is done.

The complete process step by step always ensures that the asphalt cement storage tanks that we offer for sale are complete in all respects and customer does not face any problems with the same.

Bitumen tanks are available in various sizes and with direct or indirect heating system. Mobile bitumen tanks are also offered. These tanks can be easily towed by any tailor.