Atlas provides belt type concrete mixing plant for customers in India and abroad. We have designed this reliable concrete mixing plant for customers looking for a dependable product. A successful manufacturer and exporter will provide tough quality equipment to customers. Customer delight is the long term goal for Atlas. Weighing efficiency is combined with easy operating. It helps customers in more than one way.

The concrete batching plant is designed to have modular structured components. This helps to reduce transportation and installation cost. The high degree of efficiency of the plant ensures that it is easy to produce quality concrete in a quick time. Concrete plants by Atlas have wide usage applications like dam construction, road construction, bridge construction, buildings construction, airport construction, municipality construction. They can also be used for smaller jobs which involve a small amount of concrete. The quality of ready mix concrete produced by belt type batching plant is good. It is suitable for your own use or for sale.

The most commonly available capacities are:

• 30 cbm per hour – 750/500 liter mixer

• 45 cbm per hour – 1125/750 liter mixer

• 60 cbm per hour – 1500/1000 liter mixer

• 75 cbm per hour- 2250/1500 liter mixer

• 90 cbm per hour – 3000/2000 liter mixer

• 120 cbm per hour- 3380/2250 liter mixer

• 150 cbm per hour – 6000/4000 liter mixer

• 200 cbm per hour – 7500/5000 liter mixer

Cement storage silos available in capacities 50 tons, 100 tons. Cement hoppers for cement bags are also available. The control panel is PLC type and SCADA facility is available with the same. Mobile, as well as stationary versions, are available.

We have exported belt type concrete batching plants to the Philippines, Israel, Nigeria, Myanmar, Bangladesh, Cameroon, Angola, Bhutan, Uganda, Kenya, etc.

Various concrete mixing plants to select

We manufacture and export a wide variety and capacity of concrete mixing plants from India. It ranges from 8 m3/hr. to 200 m3/hr. The machines available are stationary as well as mobile batching plants. All are made in India promising quality and reliability. With Atlas the choice is wide. Basically we categorize the same into mobile and stationary. We additionally also have a smaller version of the mobile type batching plant. We call it a mini concrete plant.

It is important to understand the basic difference between different versions and then select the best available product.

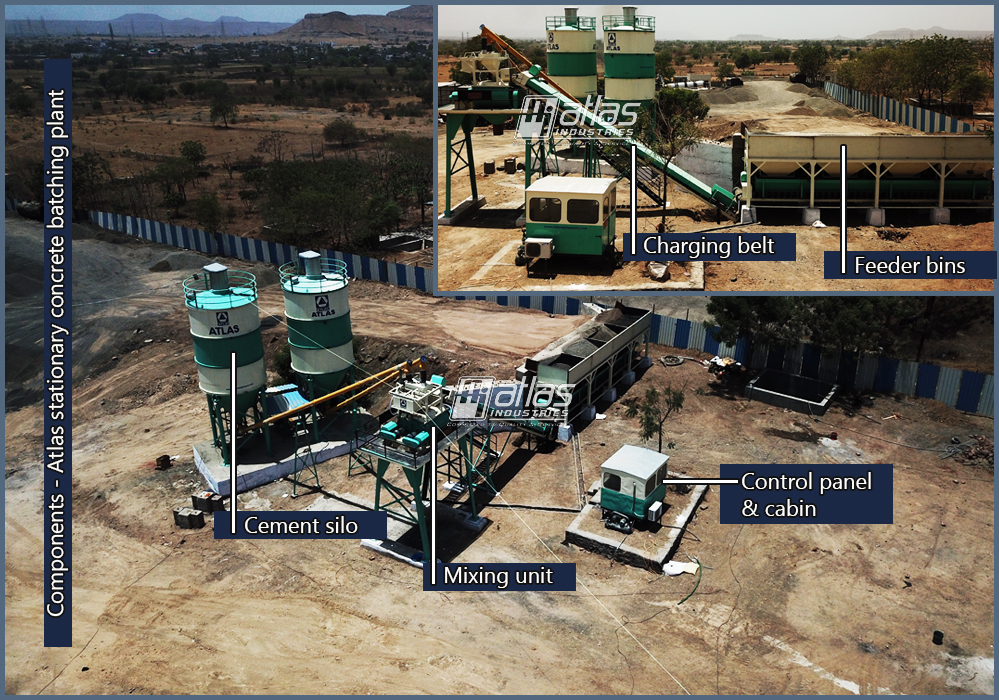

The stationary version of the belt type concrete batching plant comes in different capacities ranging from 30 to 200 cum ph. There are 4 aggregate bins for 4 different types of aggregates. These bins are inline and can store a good amount of heaped aggregates. The structure is usually bigger and heavier like a mobile plant. The plant features belt type conveyor for aggregates weighing and aggregate loading. The twin shaft mixer used here is heavy and on a strong frame. It is easy to load the ready-mix concrete on a transit mixer by this machine.

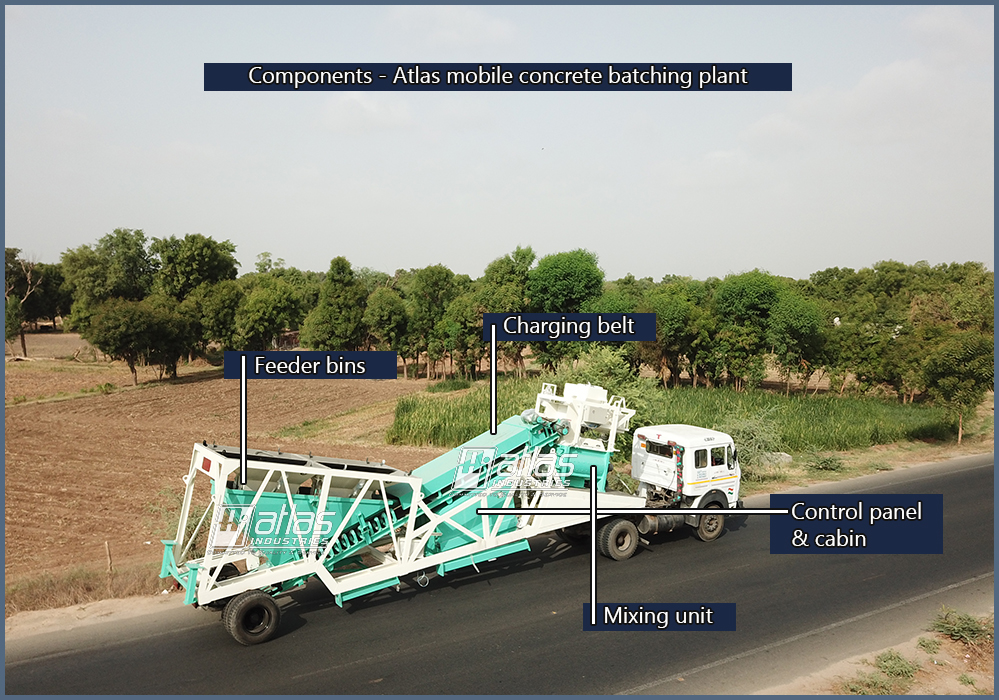

A top-quality mobile concrete batch mix plant is available in capacities 20 to 30 cbm / hr. the design is compact. The Control panel is enclosed inside a control cabin. The plant is designed to attach truck chassis via king pin mechanism. The cabin gets folded making the plant compact. The idea here is to have a belt type plant that can be taken to places. It is also possible to dismantle the same and reinstall the same at other site in a few days without hustle. The equipment is prewired with a junction box.

Mini concrete batching plant is available in 2 capacities with the option for an electric motor as well as a diesel engine. The two capacities available are 8-9 m3/hr. and 12-13 m3/hr. Both capacities are available with electric motors or diesel engines. The equipment features a small and compact design. It is with 3 bins – each one for aggregate, sand and cement. For water there is separate water weigh tank. The Control panel is easy to use and mounted on the machine.

Efficient and durable portable concrete mix plant with reversible drum mixer and low discharge height available with Atlas. The main feature of this machine is its compactness. The small size yet the efficient performance of this equipment helps complete up to medium-sized projects on time. There are 4 bins for aggregates and sand then a separate weighing system for water and cement. The separate additive tank is provided for additive addition. Cement is transferred via a screw conveyor into the cement weigh tank. The control panel is mounted on the main unit or in a separate cabin.

Main Components of Belt Type Concrete Batching Mixing Plant

Many components together make a good concrete batch plant. Apart from doing good batching and mixing it is important to make sure the mix quality is perfect. Atlas makes sure all components of batching plant work in tandem to produce good quality RMC.

Key components are as below:

Concrete Aggregates Batcher – Feeder Bins

This component receives the different sizes of aggregates that are used for preparing RMC. With the standard plant, there is a total of 4 bins for different aggregate sizes.

- Weighing of the aggregates is done individually for each bin. Aggregate weighing is very accurate assuring the good quality of end product.

- If aggregates are short of weight they will be automatically added via the computer-aided mechanism.

- The weigh batcher can also be available in 3-5 bins configuration depending on the customer’s requirement.

- The steel structure is very heavy and can withstand heavy load.

- The feeder bins can be easily loaded with loader and it has good loading width.

- There are pneumatically controlled cylinders for gate opening and closing. All this is controlled by a computer system.

- A big conveyor belt running below the bins will hold the aggregates for weighing.

- After weighing is done it will discharge the same into charging conveyor.

Charging – Transfer Conveyor

Aggregate transfer conveyor is an important part of this plant. It will accept the aggregates from the weighing conveyor and then transfer the same to the mixer unit. All the aggregates are collectively transferred to the mixing unit.

Concrete Mixing Tower – Mixing Zone

The mixing zone for concrete batch plants consists of many important components assembled together. They are mixing units and weighing scales for cement, water, and aggregates.

- It is a modular structure. Components are bolted to allow fast installation and dismantling.

- The legs are heavy ad bolted to the main chassis unit for fast installation.

- There is ample space for maintenance around the components.

- The water weighing, cement weighing, and additive weighing scales are included in this section.

- Both the water and cement are weighed by means of a load cell.

- The mixing unit is heavy. It can be twin shaft, planetary or a pan type mixer.

- Mixing units for water, additive, and cement are suspended on load cells and with butterfly valves. These are computer operated which guarantee precision.

- There is a cleaning mechanism for water. It will help to clean the mixer thoroughly with water at the end of each operation.

- The additive is separately weighed like cement and water. It is then added into the mixer for mixing.

Cement – Fly Ash Storage And Conveying

- Cement and fly ash are stored separately in a storage silo. For cement coming into bags, cement hoppers can be provided.

- Silos are crafted out of heavy steel structure to hold 50 to 100 tons of cement or fly ash.

- They come with all safety accessories and level indicators that are mandatory.

- Cement hoppers are useful for cement coming into bags which can be easily used in case of unavailability of bulk cement. These hoppers are of good capacity.

- Transfer screw conveyors for cement is provided with gear and motor.

Concrete Control Panel

- The Control panel for the concrete batch mixing plant is one of the key components. It is possible to control the full plant from a single place.

- The Control panel can work with the auto as well as manual modes.

- There is a provision for printing all-important mix material data from the control panel.

- A Control panel with SCADA is also available.

Main Advantages of Belt Concrete Batching Plant

There are numerous advantages of the belt concrete batching plant offered by Atlas. Since it is available as mobile and stationary there are many capacities available – from 10 m3 per hour to 200 m3 per hour. The software available is easy and user-friendly. Maintaining the equipment is a breeze. Design is containerized to keep the global customer in mind. Design is such that it minimizes the use of civil works. Erection and commissioning are helped by the fact that all structures are modular.

Concrete Plant Modular Structures

One of the key factors for the success of the Atlas belt type concrete mixing plant is the design. The modular structures help in fast installation. It also helps in quick loading and unloading at the job site. The transportation cost is highly reduced by the use of several modular units. It is easy to change or replace each module. Some modifications can be easily done and the equipment can be altered in the future.

Concrete Plants Mobility

The mobile version is very compact. It is a containerized design. The Control panel is with the same functions as a stationary plant which aids the easy operation of the plant. Concrete Plants mobility means that the equipment should be easy to shift. The structures and design are such that it will help shift the equipment easily. It takes less time to install the plant and also the time and effort are taken for shifting are less.

Concrete Low Running Cost

When the equipment is designed running costs and low maintenance are the important factors in our mind. The concept is to have equipment that is easy to use and maintain. The fact that the cost of spares is low helps customers in a long way. The equipment is design so that the total power required to run the same is less.

Concrete Ready Mix Quality

Quality of the final product – the ready mix is a critical factor in deciding a batching plant. If the product does not meet the required standard then it is of no use. Our equipment ensures that the final product meets the required standard. Each material is controlled and added as per weight. Accuracy is the key factor assuring a top-notch ready mix for your own use or for selling.

Reliability and Heavy Design Belt Type Concrete Plant

Any equipment has to be reliable and properly designed. Engineering plays an important role here. A well-engineered product will go a long way to ensure that your project is completed on time. Reliability is the key point of equipment by Atlas. The well-designed plants will be very reliable in the long term. We have also ensured that sufficient space for maintenance is there.

Low Cost of Spare Parts – Concrete Mix Plant

The cost of spare parts is important factor. If the spares are easily available and low cost then it is very easy for the customer to use the concrete mix plant on a long term basis.

Long term dependability, reliability and low cost of ownership is the highlight of the Atlas concrete plants. We make sure that the components that leave our factory are tested and that can last long. The equipment is installed and customer’s operators are given training at the site.