Atlas has always been in the forefront when it comes to adapting to different markets. We have always understood the customers requirement and given solutions that are customer specific. One such example is dispatch of our 160 tph asphalt batching plant to Russia. As the modern-day road contractors navigate through the different asphalt production process it is important for them to get support in form of a reliable equipment. We try to understand them and give results that work for them. This post highlights the details of the components of the asphalt batch plant that we recently exported to Russia. Everyone can see photos of the 160 tph asphalt batching plant exported from our factory.

Components 160 TPH Asphalt Batching Plant to Russia

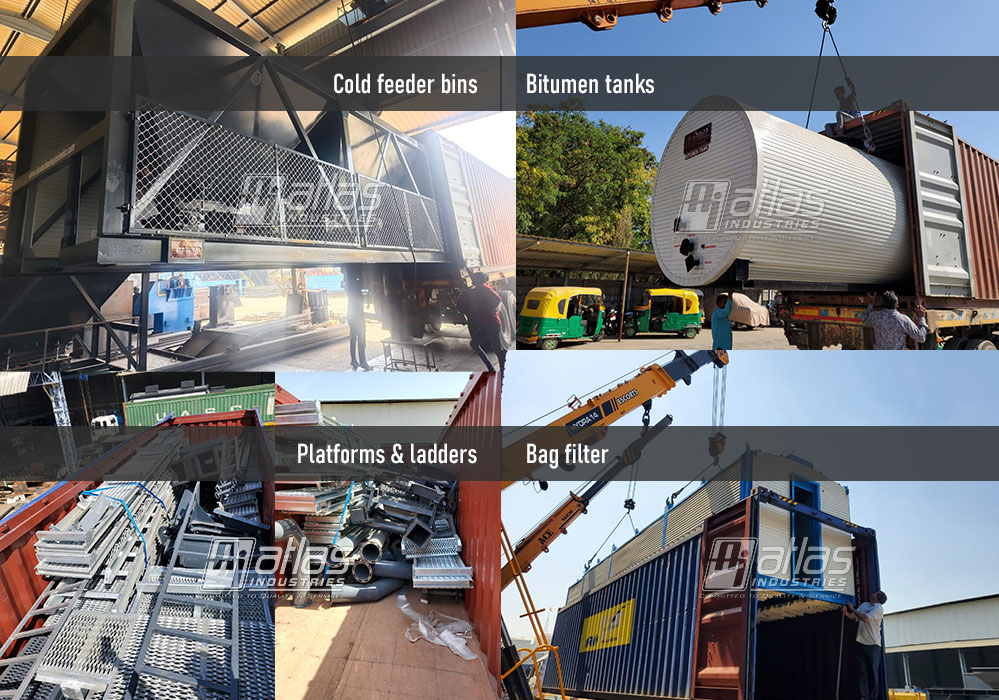

Cold Aggregate Feeding System: This crucial component ensures a precise blend of aggregates, minimizing wastage and enhancing the consistency of asphalt mixtures. We provided 6 feeder bins for cold aggregates.

Primary vibrating screen: A small scalping screen to eliminate and remove the oversized aggregates.

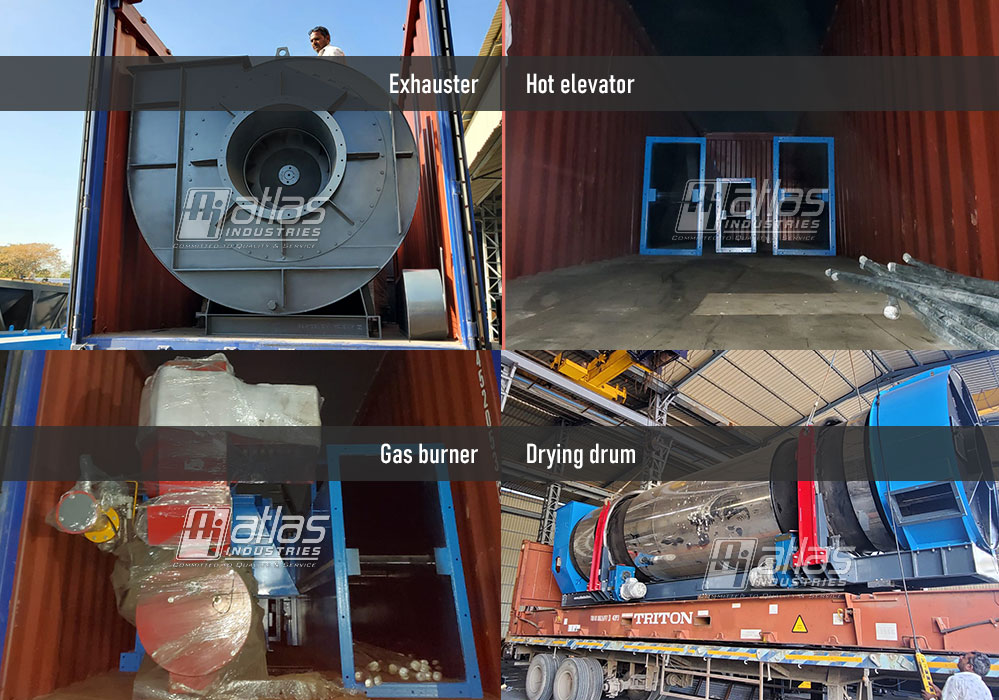

Drying Drum: With its high efficiency and optimal heat transfer capabilities, the drying drum facilitates the thorough drying of aggregates, crucial for producing high-quality asphalt mix. Here a drum with natural gas burner is provided. It is designed for working at higher aggregate moisture content.

Read Also: How does an Asphalt plant work?

Batching Tower: Central to the operation, the batching tower orchestrates the precise mixing of aggregates, bitumen, and other additives, ensuring uniformity and adherence to project specifications. It consists of below items:

Hot Elevator System: Seamlessly transporting hot aggregates to the vibrating screen, the hot elevator system minimizes downtime and maximizes throughput.

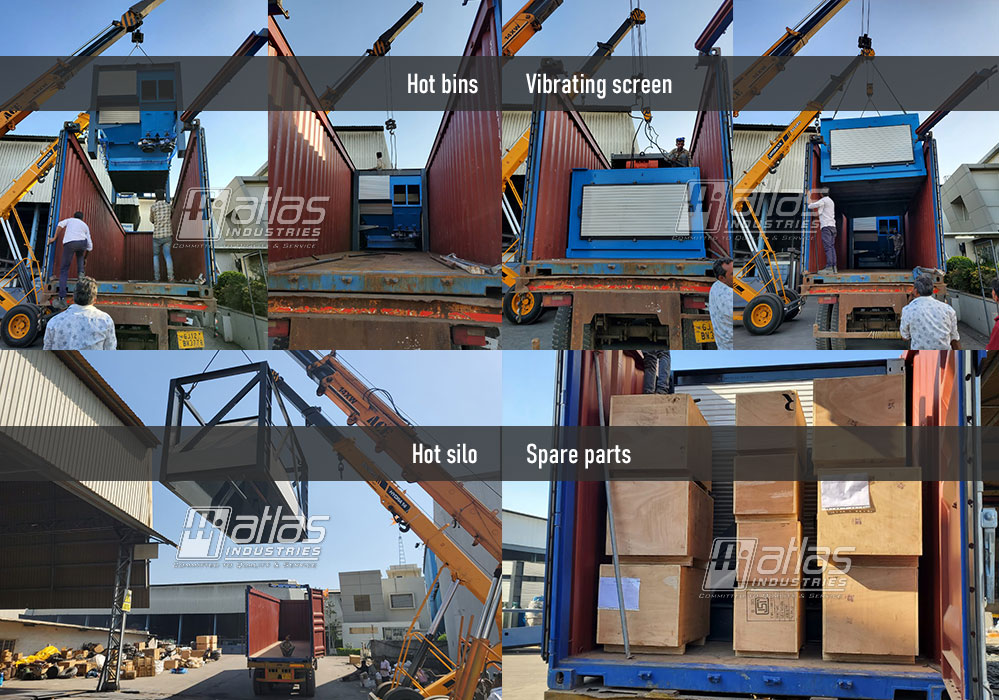

Multi-Deck Vibrating Screens: These screens efficiently separate the hot aggregates into different sizes, enhancing the quality and uniformity of the asphalt mix. For the customer, Atlas Industries has equipped this plant with a total of 6 deck vibrating screen.

Hot bins: Hot bins are equipped with sufficient storage for each material separately. It is an important unit that will store the aggregates just before addition into the mixing unit.

Mixing unit: A heavy duty mixing unit is supplied with this plant. It does a good job of mixing the contents effectively and with great quality.

Hot mix storage silo: An inline silo of 50 tons is insulated and with heating system provided with the asphalt plant. It lies under the mixer.

Bag filter: Bag filter provided is reverse flow type. It is with total of 16 pneumatic cylinders distributed over the top body of the bag house. It is capable of achieving higher cleaning efficiency.

Bitumen storage tanks: A total of three bitumen tanks equipped with this plant serves the purpose of bitumen storage and transfer. It holds a good amount of 90 tons bitumen.

Thermic oil heater: Gas burner, heavy unit suitable to heat bitumen tanks in a safe and swift manner.

SMA addition: Atlas provided SMA unit for fibre addition into the asphalt batch mix plant.

Filler silo: 30 m3 filler silo is provided with the plant to add filler material into the mix.

Control system: A control system comprising of 2 compartments. One is the special operator room is very comfortable. It also offers a computer unit with software support which is used to operate the plant effectively.

At Atlas Industries, we understand the challenges now faced by road contractors. It is their emerging and ever-changing requirement that puts us in the driver’s seat. Our design department always makes efforts to ensure that customers requirement is met and taken care of. All our equipment are carefully crafted with precision allowing customers to enjoy peace of mind. By partnering with us, road contractors in Russia can overcome improve their project outcomes make greater savings. We also help them stay ahead of the competition. As the demand for quality equipment increases, Atlas allows customers option to have top quality manufacturer with experience and support for life time. Contact us to know more and in details.