Product highlights

- Home »

- Product highlights

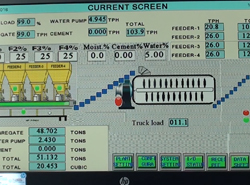

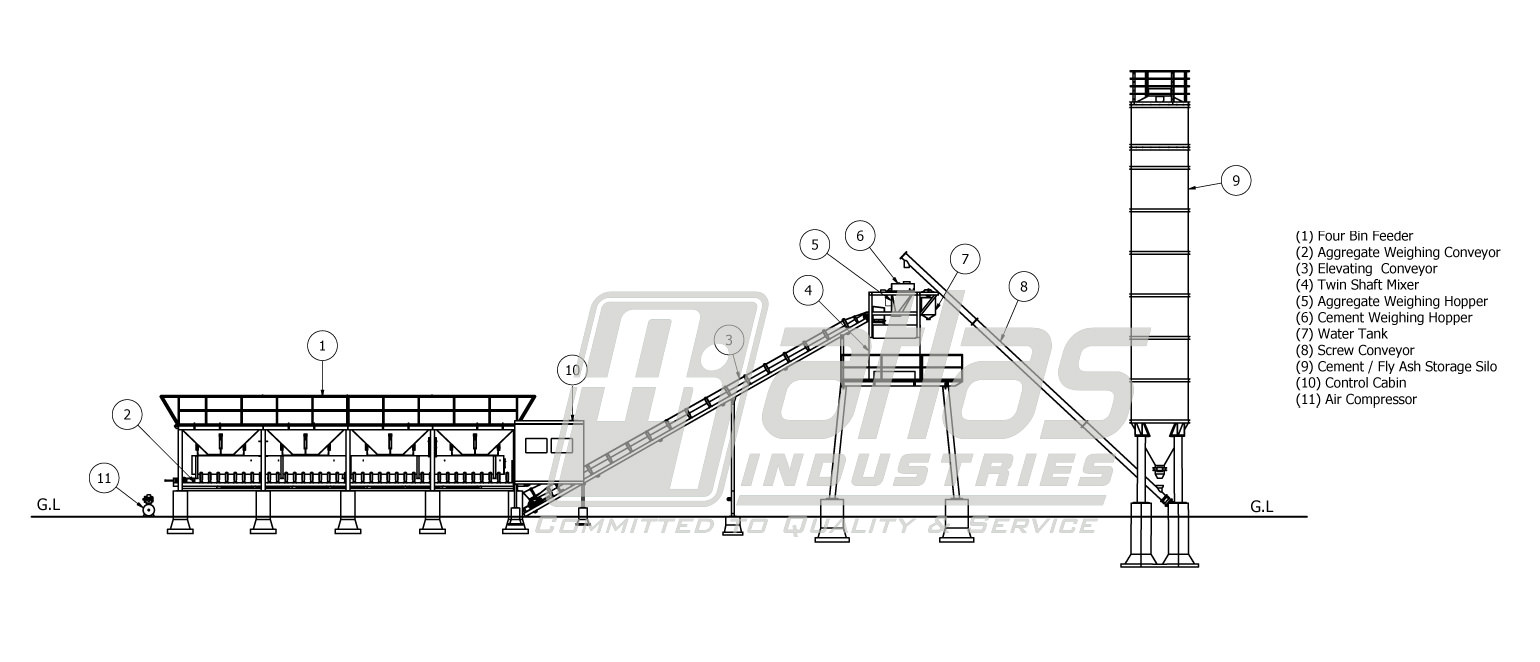

Click the link to see video of Atlas stationary concrete batch mix plant 60 m3/hr. It is a high quality concrete batch mix plant equipped with two units of cement storage silos. The mixing unit is of capacity 1500 / 1000 liters. Control panel is easy to use and comes with option to store recipes.

Atlas 260 tph hot asphalt batch plant is installed and under operation. It is provided with high quality components. The 260 tph plant offers smooth operation with durable componets. The long term reliability and super spares support allows cusotmers to have complete peace of mind.

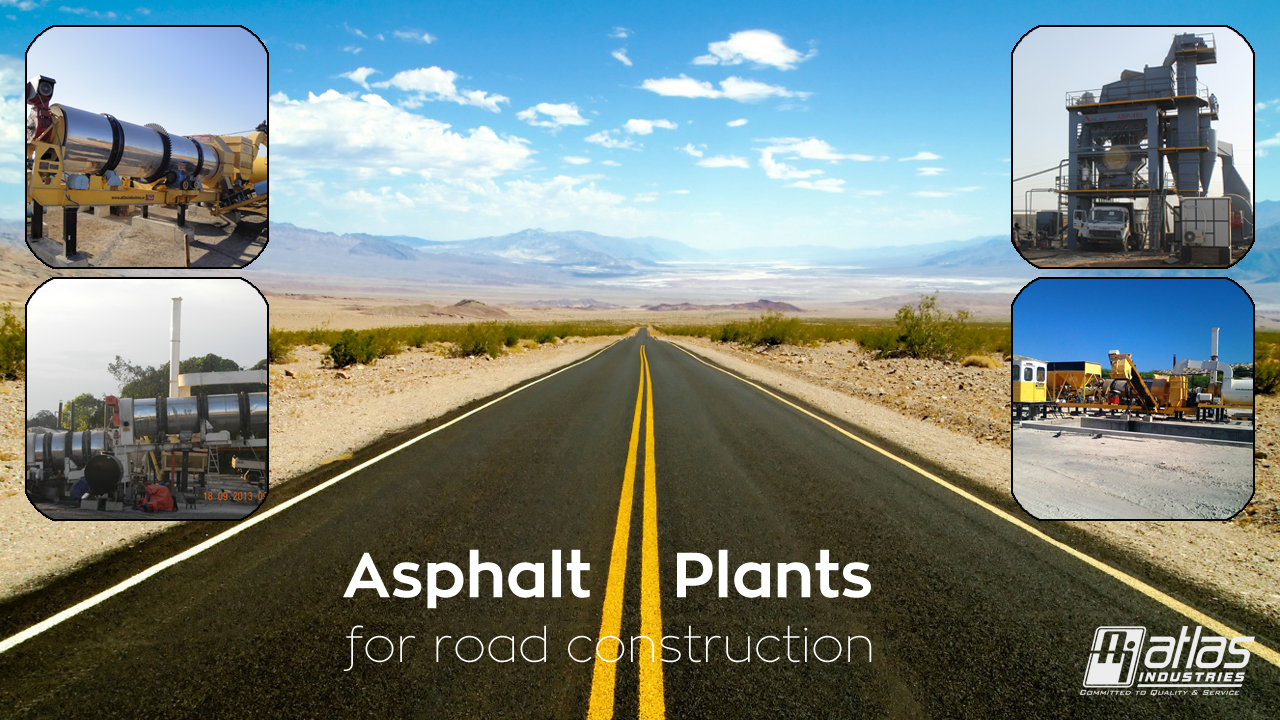

See installation video of mobile asphalt batch mix plant here. Atlas mobile asphalt batch plant is easy to install and fully mobile plant. It offers true mobility for a asphalt batch plant, it is available in 3 models and capacities 80 tph, 120 tph and 160 tph.

Atlas asphalt mixing plant comes with top notch components. It is positioned well in the market to cater to a wide variety of customers. The brand value and the trust that the equipment garners is immense. It is priced appropriately and makes a fine balance between the price and quality factor. Read the blog here.

New blog on FAQ related to asphalt batch mixing plants

See video of asphalt batch plant control panel with SIEMENS HMI and SCADA that is standard with all our batch plants.

New blog highlighting drum mix plant burner features. Burner available with diesel, LDO, FO or gas fired.

New blog: on How much an asphalt plant costs. Click to read.

PLC control panel in Atlas wet mix plant. See video.

See details of new mobile asphalt batch plant by Atlas. Available in capacities 80 tph, 120 tph and 160 tph

Read our new blog: PLC vs Microprocessor control panel

See video of Atlas single drum asphalt plant with bag filter. Counterflow Asphalt Plant is installed in Kerala, India. We have exported counterflow drum mixers to Malaysia, Ivory Coast, Spain and Tanzania. Available 20 tph to 200 tph Capacities Asphalt Drum Plant.

Click the link to read blog on difference between stationary and mobile concrete plant.

Visit us @ Bangladesh Buildcon 2018 exhibition from 12-14 July 2018. Stall number 183 - 184

See video of bitumen pressure distributor in action.

See photos of 45 m3/hr. mobile concrete batch mix plant in Myanmar

Read our detailed blog on how does a concrete batch plant work.

See photos of 160 tph asphalt batch mix plant installed near Jaipur, India

30 m3/hr. - mobile concrete batch mix plant with 2 x 60 tons hot mix storage silo installed near Mandavi, Gujarat.

See video of asphalt control plant demo given to customer who visited us from Dar es salaam, Tanzania.

See video of small 20-30 tph asphalt drum mix plant control panel. All important parameters are well explained here.

30 m3/hr. Atlas mobile concrete mixer with 60 tons silo installed in Nadiad, Gujarat. See complete video of the equipment in action.

View and download case story of mobile counter flow asphalt plant in Ivory Coast. This 90-120 tph asphalt plant is with PLC control panel.

Click below link to see photos.

See video of Atlas mobile RMC plant installed in Philippines. This is a 30 m3/hr. mobile concrete plant with twin shaft mixer. We are for sale quality small concrete mixing plant in South Africa and Bangladesh.

New container design asphalt mix plant by Atlas installed in Nashik. The equipment features better Asphalt mixing unit and bag filter unit. Asphalt batch Plant wil help lower maintenance costs and also comes with design that will help save huge money in transportation costs.

Click to see details of different types of asphalt plants by Atlas Industries, India.

Atlas 160 tph asphalt batch mix plant installed near Ahmedabad, India. Plant supplied with two natural gas burners: one for dryer and other for hot oil heater.

Click to read and download the case study and also see photos + video.

Our new blog highlights the importance of small concrete mixers for any Mini RMC Plants and the role of the reversible drum mixers in the same. Ready Mix Concrete Plant is Very Easy to Use. Mini rmc plants low initial cost and most importantly low on maintenance.

Atlas 120 tph batching plant installed near Bhatinda, Punjab, India.

Click on the linke below to see photos of the same.

Asphalt batch plant process exlained in a simple blog.

View our detailed blog on the 2 month old Atlas portable concrete mixer installed at an Industrial park in India.

See photos of portable concrete mixer installed near Bagodara, India. This plant is of capacity 20 m3/hr. and features reversible drum for mixing. There is provision to add 4 types of aggregates, cement, additive and water into the mixer. Control panel is PLC type.

Atlas 45 m3/hr. mobile concrete mixer installed in India. Plant features provision for three types of aggregates and one sand, separate weighing for each type of aggregate, sand, water, cement and additive. Control panel is PLC type with printing facility. Control panel is inside a cabin which folds inside the plant to offer maximum mobility.

See video here: https://www.youtube.com/watch?v=HJ0MJGJJKjo

See photos in the link below.

Atlas Industries manufactures different types and capacities of asphalt mix plants like the batch type, counter flow type and parallel flow type. This blog highlights the features of the different types of the plants that we manufacture.

Click the link below.

Atlas 160 tph Asphalt batch plant installed and working nicely. See video of the equipment in action.

Features: modular design, multi-fuel burner with low fuel consumption, high production, low break down, least maintenance.

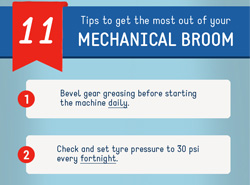

Read our blog and view tips on how to keep your mechanical broom in good condition.

Asphalt plants are of two major types and this blog discusses the differences and common components of both the types.

Planta de asfalto de 160 toneladas por hora instaladas en Rajasthan, India

Voir les photos de 120 tph expédition de l'usine d'enrobés à partir de notre usine dans le lien ci-dessous..

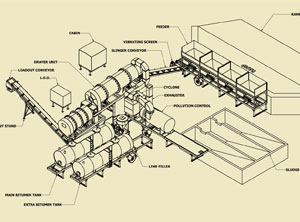

View photos of Atlas 160 tph asphalt batch mix plant installation in Rajasthan, India.

This equipment is supplied with cold aggregate feeder bins, drying drum, dry dust collector, bag house filter, two bitumen tanks, tower unit comprising of vibrating screen, hot bins, weighing section for aggregates, bitumen, minerals and mixing unit.

The control panel supplied is PLC touch screen type and with user friendly software.

Plant was dispatched with 56 tons capacity aggregates feeding unit, charging conveyor with load cells, SS coated drying and mixing drum, fuel tank for dryer burner, dry and wet type pollution control units, load out conveyor with heat resistant belt, 20 tons bitumen tank, mineral filler unit and PLC control panel inside control cabin. Batch Mix Asphalt Plant is export in Algeria. We are for sale Asphalt Mix Plant with low price.

Since we strive for customer delight, we supplied this plant with few complimentary spare parts. The customer is based in Algeria.

View and share photos from the link below.

Customer from Ghana ordered a standard mechanical broom machine. This equipment is easy to use as the customer can cleanner broom the road by just attaching it with a towing vehicle. Atlas is manufacturer of mechanical broom machine.

See the photos of the sweeping equipment in the link below.

Our second 160 tph asphalt batch plants was dispatched yesterday for the construction site. The plant is of capacity 160 tph with two bitumen tanks, modulating burner and bag house filter. Site photos will be updated as soon as the Asphalt plant is erected and running.

Atlas blog was due for redesigning siince long time. Finally the work is done and our blog is running on a clean and mobile friendly design and is faster than before.

You can check the blog on your phone, tablet or computer device for superb experience.

Some of the features to look out are: Categories, Contact form and Recent posts on the left side.

Navigate the blog in the link below.

It is a happy moment for us as we will be manufacturing 90-120 tph counter flow asphalt plant for a customer from Spain. The plant will be featured with counter flow technology with a pug mill mixer, baghouse filter and provision to add RAP material into the mixing unit.

We are very happy to announce that our first concrete batch mix plant of capacity 20 m3/hr. is installed in Bhutan. This plant was with twin shaft type mixing unit with planetary gear box.

Click here >to learn about the product in details, download specifications, catalog and view videos.

We are happy to announce that we have confirmed orders for two asphalt batch mix plants - 120 tph and 160 tph.

We will be supplying these equipment with bag house filters.

Both the plants will be ready by the end of June, 2014.

We will be shortly starting production of a 90-120 tph stationary asphalt drum mix plant for our customer based in Algeria. This plant will be complete in all aspects with four bin feeder for cold aggregates, fully insulated drying and mixing drum, 1 x 20 tons bitumen tanks, PLC type control panel, etc.

This is our first asphalt batch mix plant of capacity 80 tph. We are offering asphalt batch mixing plant in the capacities 80 tph, 120 tph and 160 tph.

Click the link below to view photos.

Concrete mixers ideal for small sites are available in 4 models and in capacities: 10 m3/hr. to 25 m3/hr.

These plants come with separate weighing system for aggregates, cement, water and additives. PLC control panel is also available with this mobile concrete batch plant.

Click the link below to see product details.

Twin shaft mixers manufactured by Atlas come with option of greasing all the moving parts of mixer. By using a grease gun, required amount of grease can be pumped to all the points so that the mixer works smoothly.

Read more about twin shaft mixers on the link below.

Atlas Industries supplied, installed and erected 40-60 tph mobile asphalt plant in American Samoa.

This plant was a standard 40-60 tph plant with 32 tons cold feed storage, covered charging conveyor, drying and mixing unit, 15 tons bitumen tank, mineral filler, fuel tank for dryer burner and covered load out conveyor.

The plant is fully mobile plant with units mounted on chassis complete with axles, wheel hubs, trailer towing pins. The mobile asphalt plant is pre wired with cables, socket, plug, junction box to interconnect the units.

Motors used in the plant are of rating 220 V - 60 Hz.

Atlas manufactured mobile asphalt plant of double drum type and of capacity 90-120 tph.

Click on the link to view pictures.

Atlas Industries supplied 60-90 tph double drum plant in Jaipur, India. This asphalt plant consists of four bin type aggregate feeder, charging conveyor, drying drum for aggregates, mixing drum, mix material load out conveyor with 5 tons hot mix silo, two bitumen storage tanks and wet dust collector unit for pollution control.

Click on the link to view photos.

Our concrete mixers come with PLC touch screen type control panels which have very user friendly software and advantages as stated next: printing facility (printer attachment), 99 recepies can be stored, last 800 batch data can be saved in display, storage in external media like pen drive is possible, all parameters can be seen at a time in a singe display.

The plant offered to customer was with common five bin aggregate feeder, a pug mill, load out conveyor, 25 T Wet mix storage SILO, drying and mixing drum, LDO tank, load out conveyor, mineral filler, pollution control unit and control cabin with panel. For collection and recycling of the dry dust we gave screw conveyor. The screw conveyor transferred the dust from the dry dust collector to the mineral filler.

Download catalog to view case study for Atlas combined asphalt drum mix plant and wet mix macadam plant.

Click on the link to view plant pictures.

This is first double drum plant by Atlas Industries exported to Malaysia. The plant is equipped with aggregate feeder, drying drum, mixing drum, two bitumen tanks of 30 T each, wet dust collector, PLC type control panel, 2 x 25 T hot mix material storage silo.

This dry concrete batching plant is supplied with 120 T feeder, charging conveyor, twin shaft mixer, 30 T storage hopper, PLC based control panel board.

In Pug mill we have 6 pedestal - UCF 218.

Our shafting used in the pug mill is of 5 inches.

We do not make slots in the shaft to fit pedal arms. We have given distant pieces to increase the life of the Shaft.

Our design is that we have two arms opposite to each other and similar with tips. Others have alternate arms and tips we have double arms and tips.

Dust coming from the dryer drum of the asphalt plant can be transferrred to the mineral filler via a screw conveyor. The picture shows screw conveyor being used to transfer the dust to the mineral filler to recycle it to the drying drum.

All our mobile asphalt plants and concrete plants come with junction box on each chassis.

Junction box at each chassis help save time in assembling and moving the equipment.

PLC panel is compact compared to the microprocessor based panel. The PLC panel is also very low on maintenance.Programming can be customized which is not possible on Microprocessor based panel.

Programming can be changed from the manufacturers end as per customers requirement and can be easily incorporated by the client at his site.

Atlas mobile concrete batching plants come with foldable control cabin so that you can dismantle and reinstall the plant in quick time.

Also allowing you to save a lot on the transportation costs.

Plant is available in capacities 20 m3/hr., 30 m3/hr., 45 m3/hr. and 60 m3/hr.

Friction drive can be supplied in the drying and mixing drum of the drum mix plants above 90 tph upon request of the customers.

If your wet mix recipe asks you to add cement, we can help you with the same.

Depending upon the percentage of cement to be added, we can supply you with suitable silo. Provision can be done in the panel board for the same.

Atlas mobile drum mix plants come with pneumatic braking system for additional safety.