Hot mix asphalt material for paving is usually a mixture of graded, high quality different sizes of aggregates which are heated and mixed with liquid bitumen in measured quantities to produce hot mix asphalt. Asphalt is a paving material made out of crushed rocks and bitumen.

Apart from the relative amounts and types of aggregate and recycled asphalt pavement used to produce hot mix asphalt, characteristics of hot mix asphalt is determined by the amount and grade of bitumen used while making the asphalt.

Hot mix asphalt production requires drying and heating of aggregates so that bitumen can be coated easily. The drying process involves drying of the aggregates in rotating, slightly inclined dryer drum equipped with a burner. Aggregate is introduced in the higher end of the drum. Interior of the drum is equipped with different types of flights that help in properly heating the aggregates and also aid in properly coating it with bitumen

Two basic types of asphalt plants are:

- Batch plants also known as discontinuous tower plant – Batch plants make asphalt in batches.

- Drum plants also known as continuous plants – Drum plants make asphalt continuously.

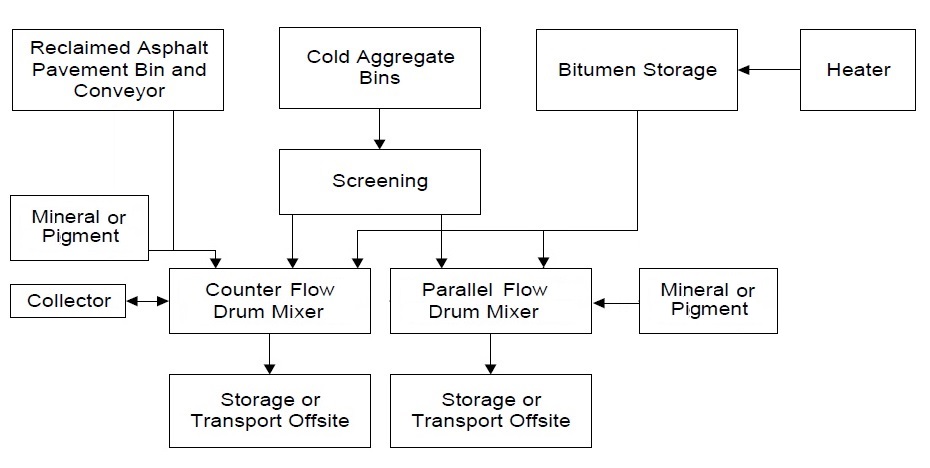

Drum plants can be parallel flow and counter flow drum mix plants.

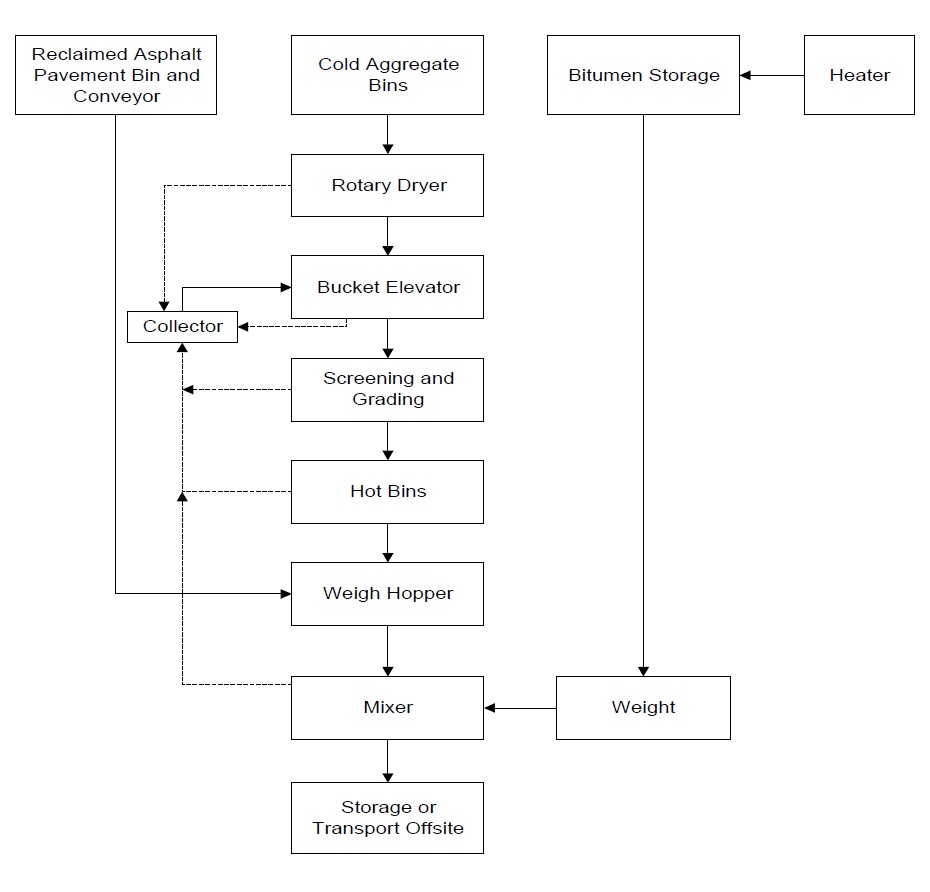

Batch mix plants:

The batch mix plant process begins when the aggregates is placed in appropriate bins of the aggregate feeders. The aggregates are then transferred to the drying drum by means of a conveyor. Drying drum is equipped with flights internally to promote drying efficiency. Once the aggregates leave the dryer, they are transferred to vibratory screen which does the task of separation of aggregates according to the size and the aggregates are dropped into the separate hot bins.

BASIC PROCESS OF ASPHALT BATCH PLANT

Since the aggregate size distribution is controlled, the desired aggregates and desired type is allowed to enter the mixing unit of the asphalt plant where it gets mixed with the liquid bitumen which comes pre-weighed from a heated storage tank. The mixing of asphalt and aggregates takes place in desired proportion as required in the final mix. Hot mix asphalt is then dropped into a hot storage silo or a truck.

Parallel flow asphalt drum mix plants:

The process of making asphalt in this plant is continuous process unlike in batches as seen in the batch mix plants. Here the dryer is used to dry as well as mix the aggregates along with bitumen. Weighing in drum mix plants takes place on the charging conveyor belt when the material is being transferred from the cold feed bins to the drying and mixing drum. The mixer is discharged at the lower end of the drum where it can be stored in the silos or discharged on the trucks.

In parallel flow asphalt mixer, usually dry and wet dust collector type pollution control devices are used.

BASIC PROCESS OF ASPHALT DRUM PLANT

Here the aggregate in the drum moves in counter or opposite direction to the burner flame. The liquid bitumen mixing zone is located behind the burner flame zone so that the burner flame does not come in direct contact with bitumen.